When working with aluminum over sheet metal, several variables need to be considered. Aluminum is typically thicker and stronger, and requires more force to bend as well as consideration of edge conditions and punch nose radii. This free chart outlines what bend radii is required for the approximate thickness of aluminum. We recommend printing it out to keep as … The Minimum Bend Radius for Aluminum

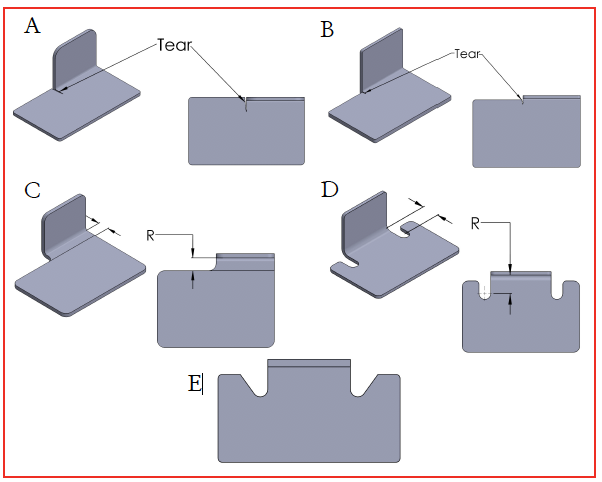

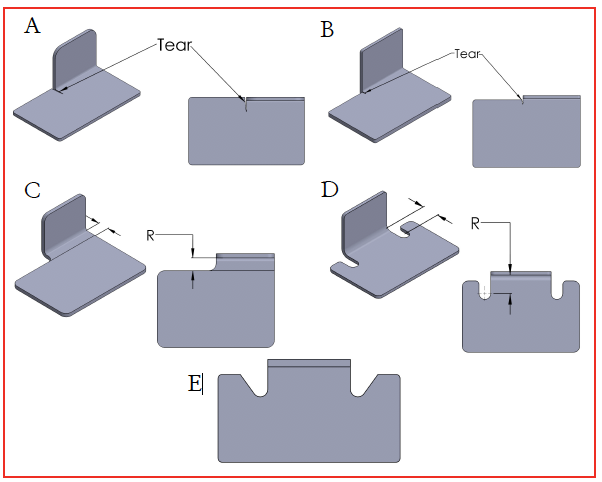

The position of the metal form is vital for the success of your project. Diagram “A” illustrates a design that is not desirable for quality or economy. When the form is inside the blank profile, as shown, the material must be torn through the stock thickness and the bend radius. If the part is under … How to Position the Metal Form

During shearing and punching, there are a number of factors to keep in mind to improve edge conditions. On ferrous materials, the clearance between punch and die should be about 8% to 10% of the material thickness, which may vary due to hardness and thickness. The punch and die clearance will differ on various non-ferrous … 3 Ways to Improve Edge Conditions

Many metal stampings require holes, but there are several considerations when choosing where to place a hole and how to pierce the hole. To pierce holes with economical tools and operations, the hole diameter must not be less than the stock thickness. If the hole diameter is less than the stock thickness (or less than … How to Pierce Round Holes in Metal Stampings

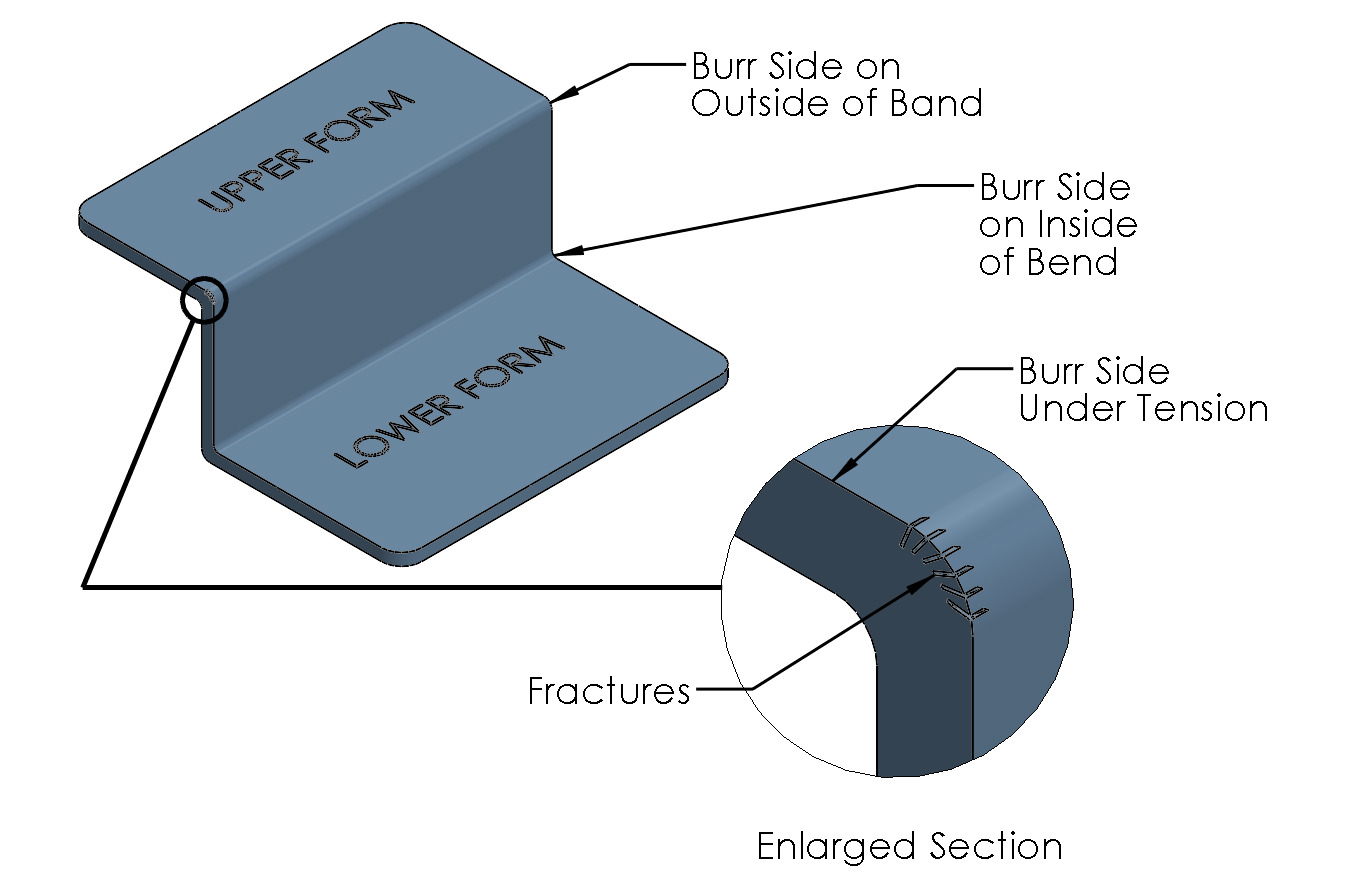

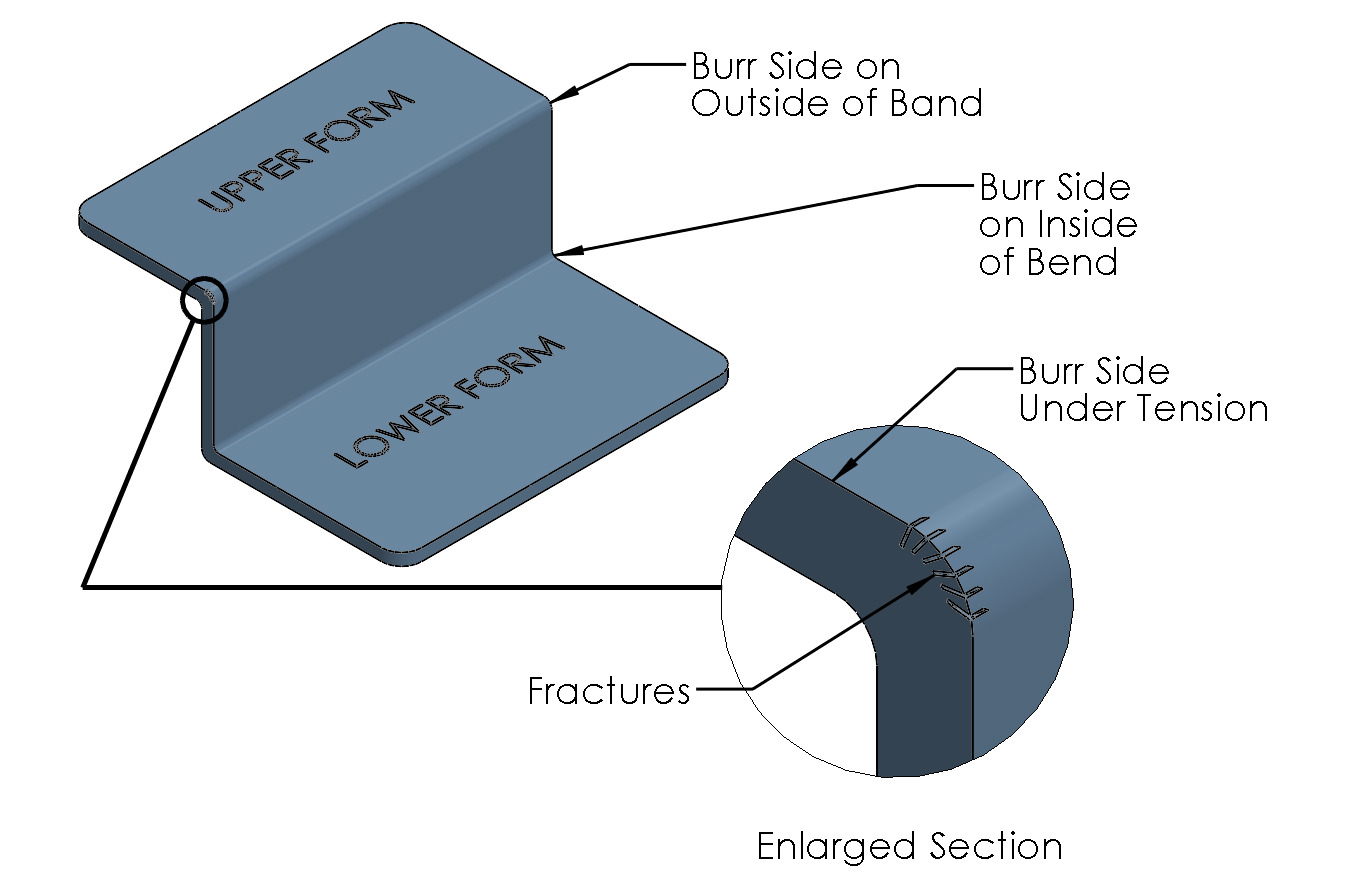

Distortions are sometimes unavoidable while metalforming, but if youre you are encountering fractures in your metalforming pieces, there are a few steps you can take to prevent them. The illustration below shows a fracture condition that occurs when the burr side of the blank is on the outside of the bend. This fracture condition occurs … How to Prevent Fractures in Metalforming

This year, Dayton Rogers turns 90! In 1929, Dayton A. Rogers founded a new manufacturing company and altered the business of metal manufacturing forever. 90 years later, his legacy continues as Dayton Rogers impacts the world of manufacturing with its innovations now and into the future. Our Timeline 1923: Dayton A. Rogers sets out to … Dayton Rogers Turns 90!

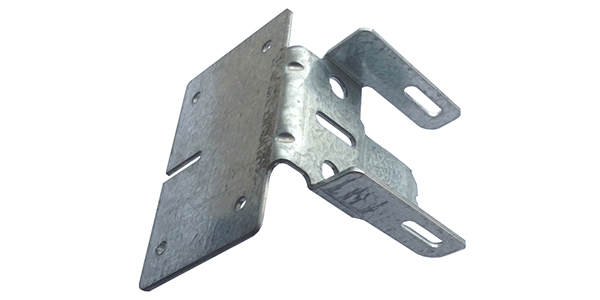

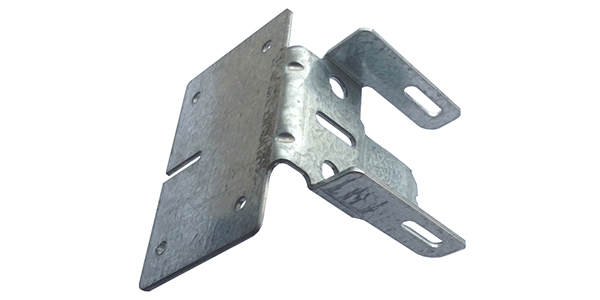

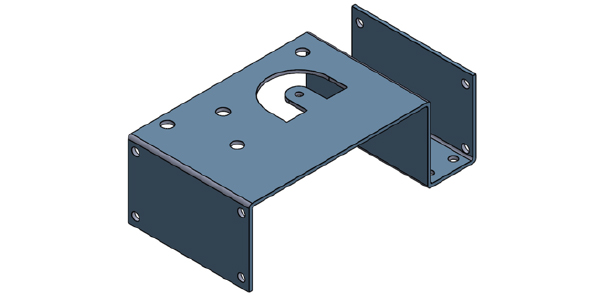

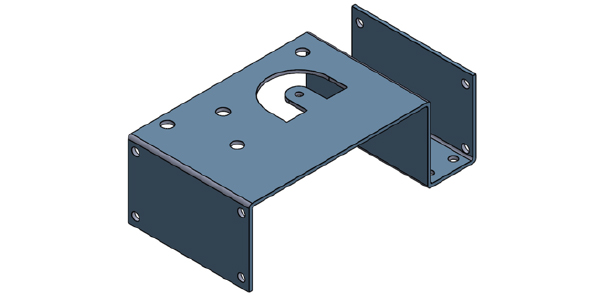

Comparing cost impact of the several variables is difficult. To help explain the impact, we have selected a sample part and shown the price range that you could reach depending on how you control your design. Low Cost Design Tolerance: + .010 on centers — + .005 on hole diametersMaterial: 16. ga. 1010 sheet — … Typical Parts Price Comparison of Variations in Materials and Design/CAD

Here at Dayton Rogers, we live and breathe metal stampings. As an authority on the subject and stamping fanatics, we often forget that not everyone is familiar with how different types of stampings work. You may have heard the terms “short run stamping” and “progressive stamping” before. What exactly is the difference between the two? … Short Run Stamping vs. Progressive Stamping: Which is Right for Your Project?

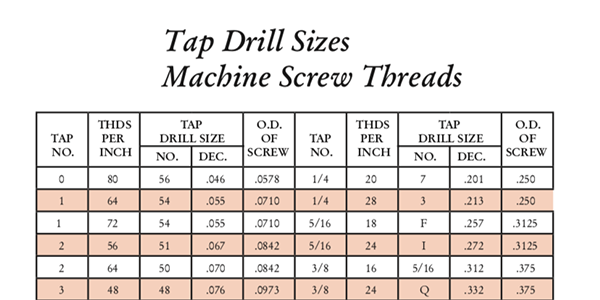

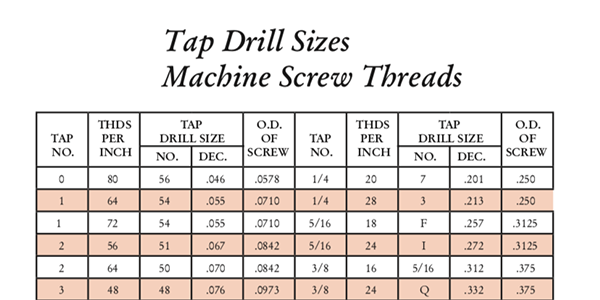

A majority of threads made in manufacturing are machined using taps. Cutting Taps are an important tool for creating internal threads. What are Cutting Taps? North American Tool defines them as: [Cutting Taps] are tools that are designed to remove material from the hole leaving a finished internal thread form in the geometry intended. These tools utilize … Cutting Tap Drill Sizes [FREE CHART]