Posted: Nov 8, 2018

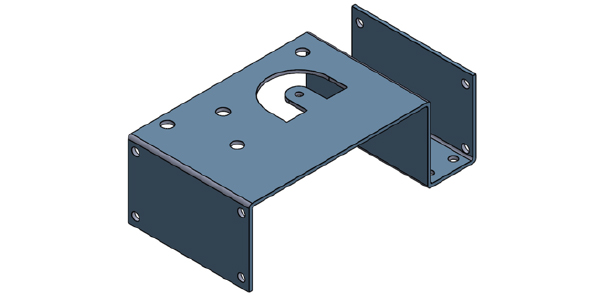

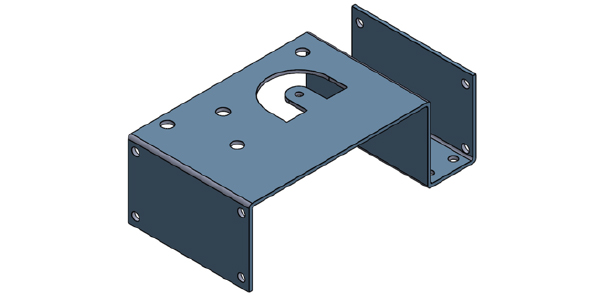

Comparing cost impact of the several variables is difficult. To help explain the impact, we have selected a sample part and shown the price range that you could reach depending on how you control your design.

Tolerance: + .010 on centers — + .005 on hole diameters

Material: 16. ga. 1010 sheet — standard tolerance .059 + .004

Bends: Radius inside = to material thickness

Hole distortion: Print should note “distortion permissible” if hole is too close to a form

Outside corners: 1/16” radius allowed

Debur: Break sharp edges

Tolerance: + .002 on centers — + .001 on hole diameters

Material: 1010 strip steel — .059 + .003 thickness

Bends: Inside .000 to .015 radius

Hole distortion: Not allowed

Outside corners: 0 -.015 radius allowed

Debur: .010 Max/Min

Choosing your design for any part requires several considerations. Request a quote today to get started.

Want more information on parts and design? Get your FREE copy of the signature Dayton Rogers Red Book (2018 Metalforming Design Handbook: Cost Effective Design Principles). This powerful book is your resource for all things metalforming and stamping.

Dayton Rogers is your trusted resource for sheet metal fabrication, metal stamps, metalforming and all your manufacturing company needs. Get a free quote today on your custom metal fabrication project.