How Does Deep Draw Metal Stamping Work? Table of Contents Deep draw metal stamping is a fascinating and intricate manufacturing process used across various industries, including automotive, aerospace, and defense sectors. While many of the basic tenets of metal stamping apply to deep draw applications, there are some key differentiators that make this process more … How Deep Draw Metal Stamping Works

Types of Tooling for Short-Run Metal Stamping Explained Tool and die-making is an intense process that plays a key role in creating countless parts that are part of our everyday lives. Beyond that, it is also an intricate skill that requires years of training to enter, and decades of experience to master. In today’s article, … Types of Tooling for Short Run Metal Stamping Explained

Why Choose Short Run Metal Stamping? At Dayton Rogers, we’re proud of our global legacy as the pioneers of the short run metal stamping process. As a lifelong leader in the field, we’re often asked- why choose short run stamping? With so many other types of metal forming available to choose from, what makes short … Why Choose Short Run Metal Stamping?

Develop A Rapid Prototype at Dayton Rogers Staying ahead in a manufacturing niche often means being able to swiftly bring ideas from concept to reality before your competitors. For companies seeking a partner to not only prototype their metal stamping projects but manufacture them with precision, Dayton Rogers stands out as a beacon of … Develop A Rapid Prototype | Dayton Rogers

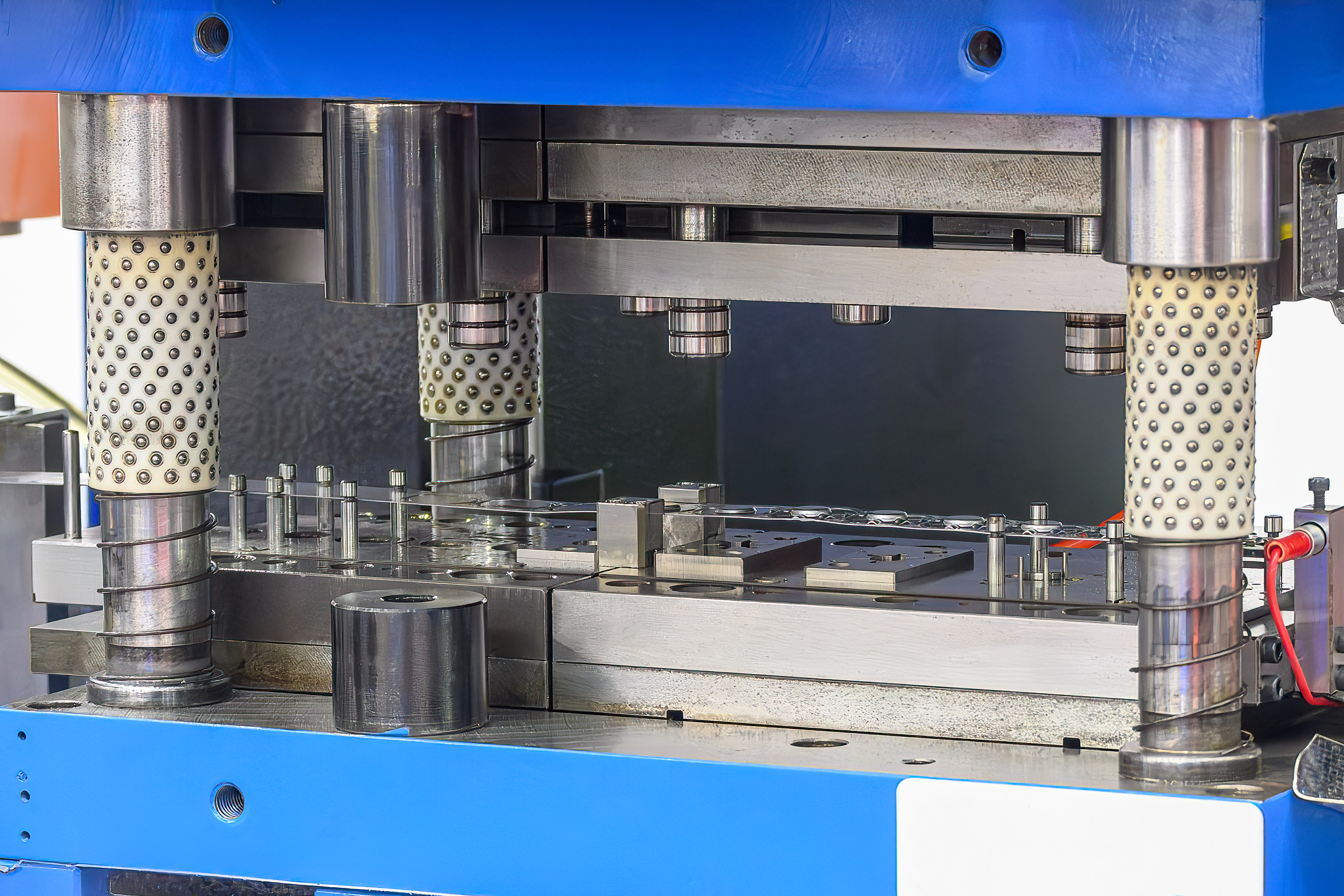

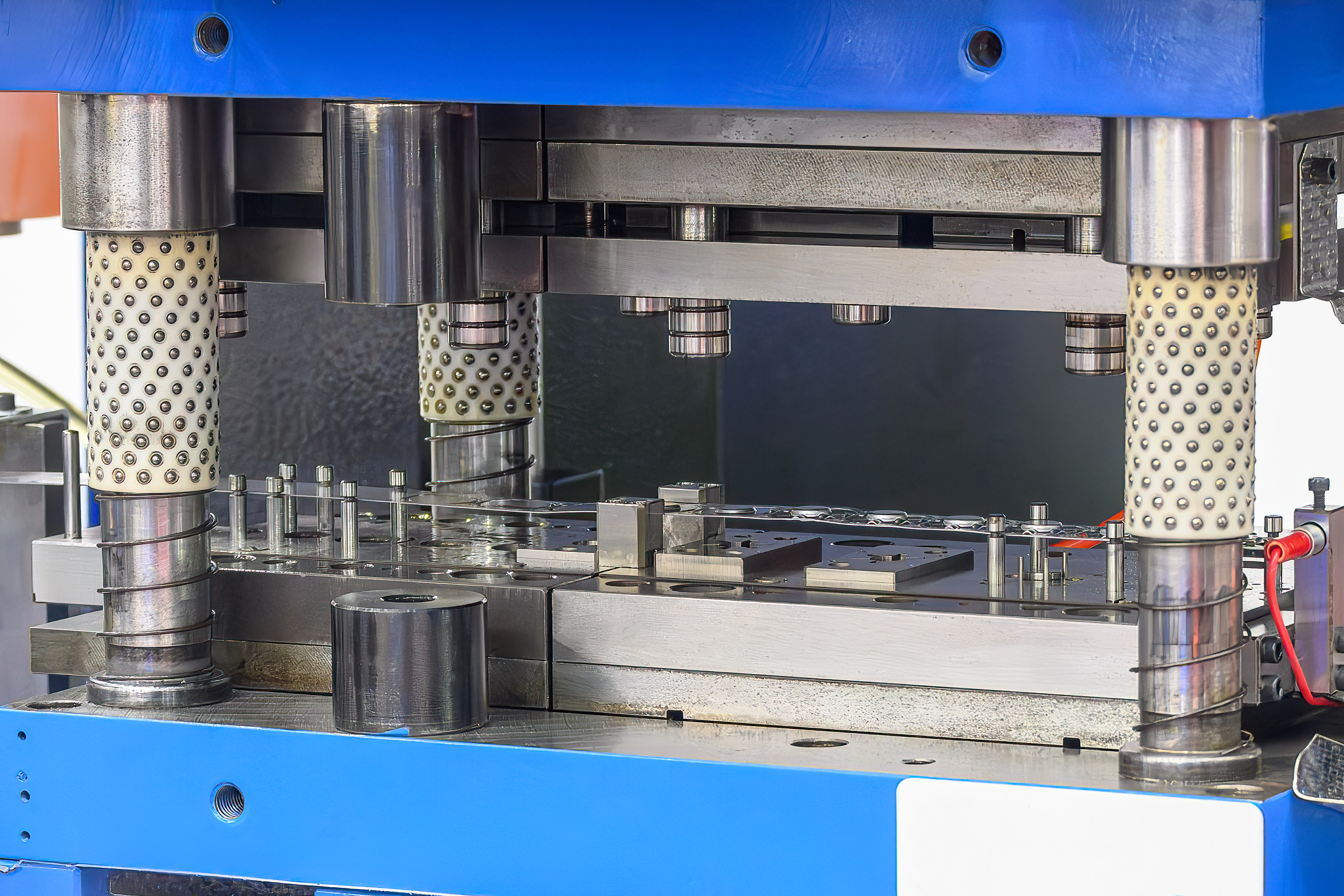

The Ultimate Guide to Progressive Stamping Here at Dayton Rogers, one the metal stamping processes we offer to our customers is progressive stamping. Progressive stamping involves feeding a strip of metal through a series of dies to create a finished part with every stroke of the machine. Since each cycle produces a new finished piece, … The Ultimate Guide to Progressive Stamping

The Role of Metal Stamping in The Firearms Industry Metal stamping is a versatile style of metal forming that can be strategically utilized to minimize production time, bring down manufacturing costs, and ensure part repeatability across a range of industries. One such sector that benefits from the perks of metal stamping is the firearms industry, … The Role of Metal Stamping in the Firearms Industry

Automotive Fabrication for Motorsports at Dayton Rogers The fast-paced world of motorsports elicits unparalleled levels of excitement from fans, participants, and engineers alike. There is truly no other venture pursued by manufacturers and fabricators the world over that gets people’s hearts racing the same way that racing itself does. Performance vehicle builds are some of … Automotive Fabrication for Motorsports at Dayton Rogers

How Welding Fabrication Complements Metal Stamping Welding fabrication and metal stamping are two essential processes in the manufacturing industry. While metal stamping involves shaping and cutting metal sheets, welding fabrication involves joining metal pieces together. These two processes often go hand in hand, with welding fabrication complementing metal stamping in many ways. In this article, … How Welding Fabrication Complements Metal Stamping

Can You Really Save Costs with a Custom Metal Stamping? When it comes to metal manufacturing, there are a variety of methods to choose from. Custom metal stamping is one such method, often selected for its ease of setup and quick turnaround time. While standard metal stamping tooling can be effective, there are some cases … Can You Really Save Costs with a Custom Metal Stamping?