While metal stamping is at the heart of our business, Dayton Rogers has strategically incorporated secondary welding services to offer a one-stop solution for your metalworking needs. Welding is the perfect complement to our classic metal stamping and other fabricated metal parts. By entrusting us with your welding requirements, you benefit from the seamless integration of Dayton Rogers’ services all performed under one roof. This synergy results in unmatched efficiency in your production processes and consistent quality between every unit of your product. Our welding services not only simplify your supply chain but also add significant value to your products, all while keeping your costs in check. We offer a versatile array of welding techniques tailored to suit a variety of projects. Our welding portfolio includes the following:

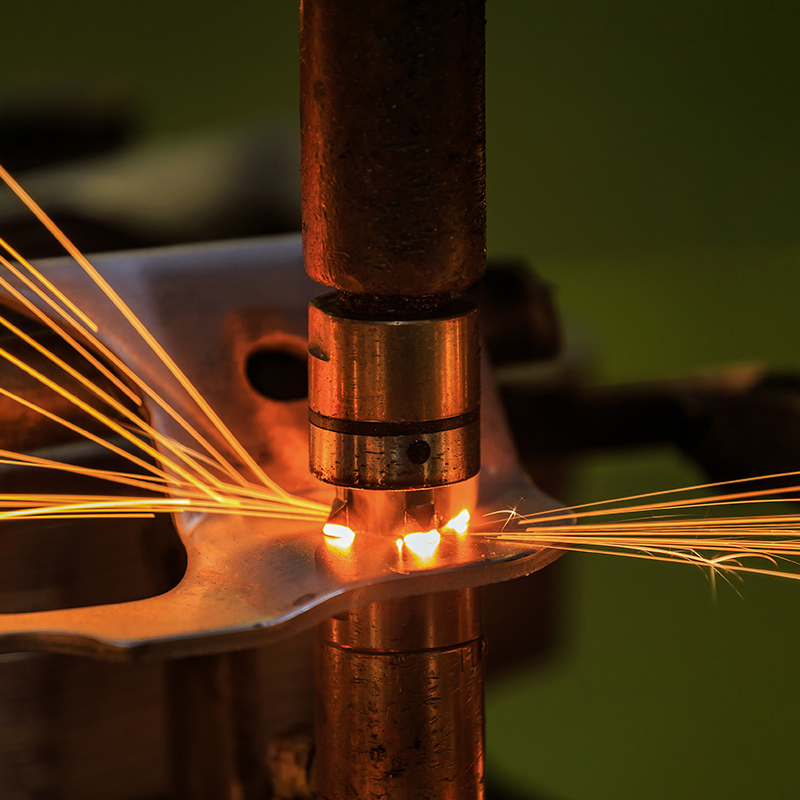

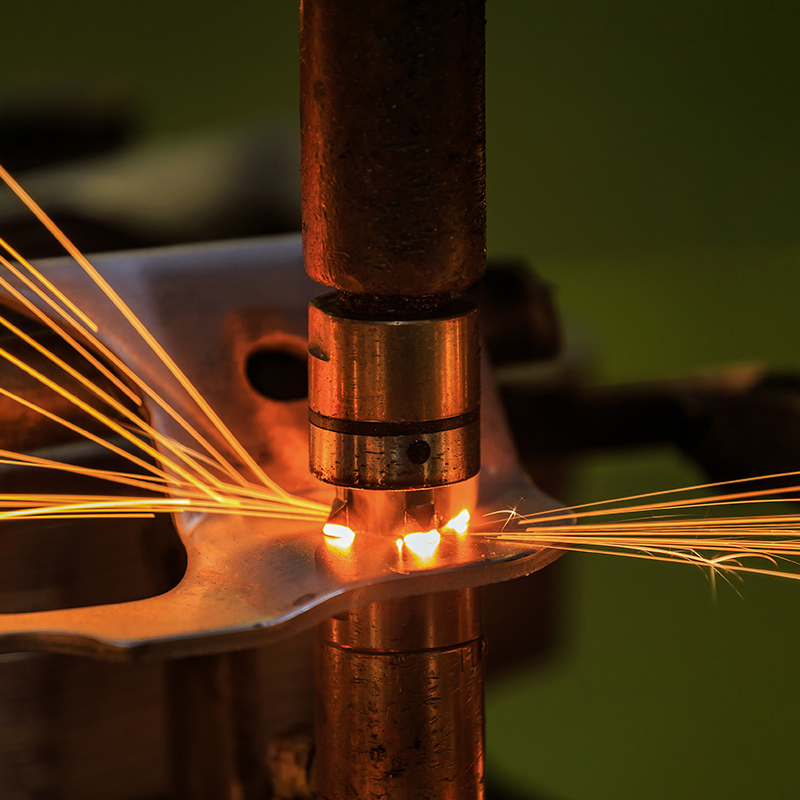

Spot welding is the simplest of all the welding processes, which makes it the quickest and most cost-effective method that we offer. This type of welding is commonly used to weld metal sheets together, creating a permanent bond between the two. One significant advantage of spot welding is its ability to join metals quickly without additional filler material or extensive preparation processes like cleaning or fluxing. This makes it ideal for mass production where time efficiency is crucial. This method is suitable for joining low carbon steels, stainless steels, nickel-based alloys, and titanium for use in various industries including automotive, construction, and manufacturing.

Arc welding delivers high strength bonds in a cost-effective manner. This method is substantially more versatile when compared to the other welding options we offer, suitable for many materials including:

And more. Our skilled technicians expertly apply a professional grade weld to ensure a strong bond on your final piece.

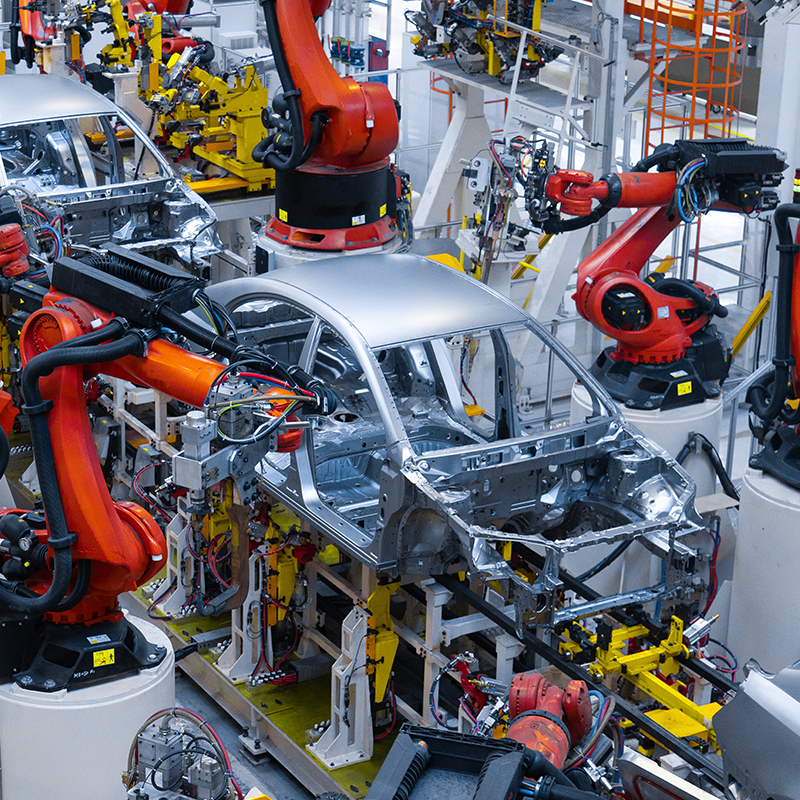

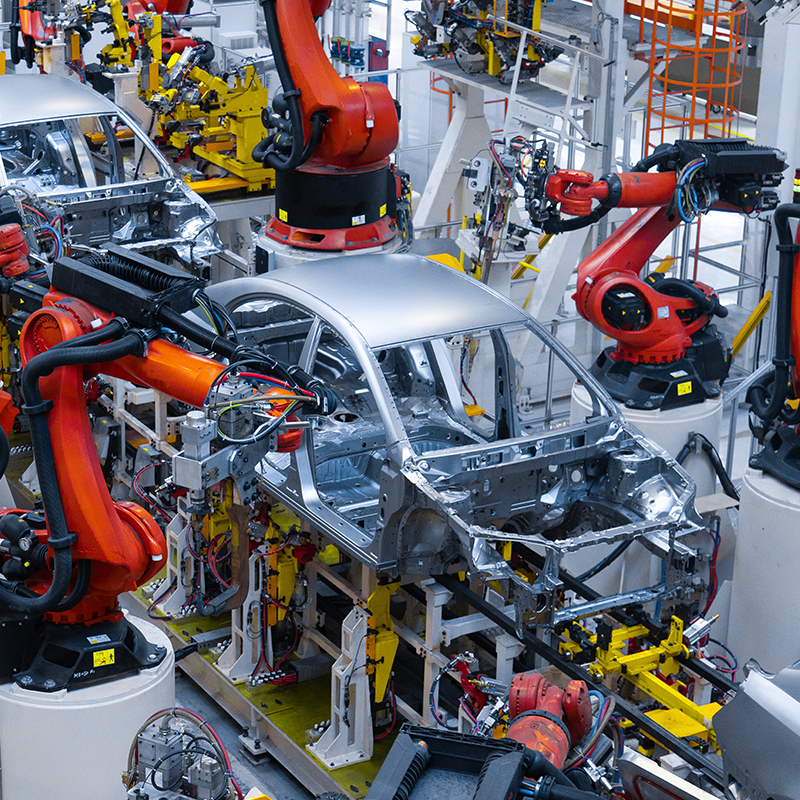

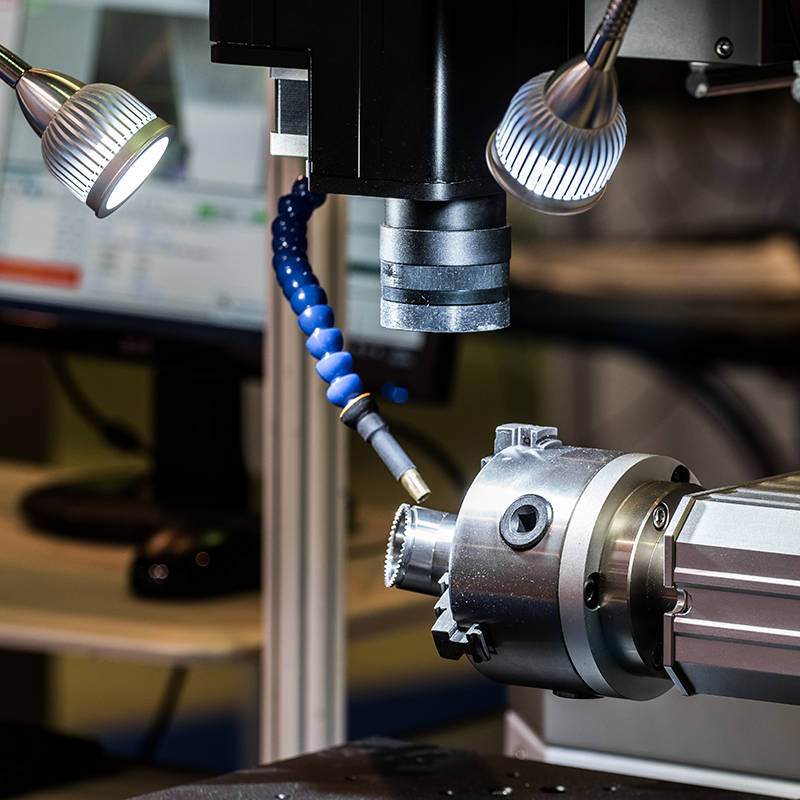

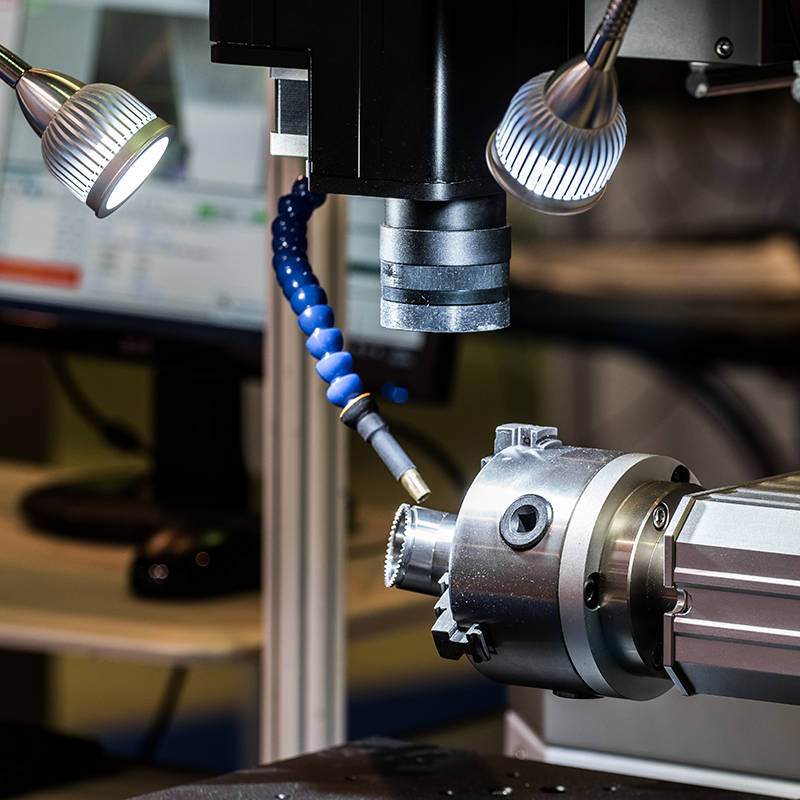

Our robotic welding equipment is the most advanced of our current weldment offerings. This method is best suited for high production, high precision applications where repeatability is made easy thanks to the use of a programmed weld path. We recommend this type of weld for high-precision applications.

Metal Inert Gas Welding (MIG) and Tungsten Inert Gas Welding (TIG) are used for welds where high strength is critical. They both employ very high heat and slow cooling times to make an incredibly durable joint between parts. These methods also allow us to weld different metals and alloys to each other, so working with mixed materials is not a problem. Each method calls for the use of a filler material to bond the two metal pieces together, which is selected based on the materials to be joined. The welds produced by MIG and TIG are shielded by an inert gas, which makes them more visually appealing than flux-shielded arc welds.

While metal stamping is at the heart of our business, we’ve strategically incorporated secondary welding services to offer a one-stop solution for your metalworking needs.

Metal stampings are the backbone of the automotive industry, providing the foundation for vehicle components. Welding plays a pivotal role in enhancing these components by offering:

Structural Integrity: In auto manufacturing, combining metal stampings with various welding techniques, such as spot welding, MIG, or TIG welding, ensures the structural integrity of critical components. This includes chassis, frames, and body panels, all of which require precise welding for safety and durability.

Customization: Welding enables auto manufacturers to customize vehicle components, such as exhaust systems or suspension parts. The flexibility of welding allows for tailored solutions, which can enhance performance, aesthetics, and overall functionality.

All manufacturing tier levels across industries rely on metal stampings for the production of their projects. Welding provides value through:

Enhanced Durability: By incorporating welding methods like SMAW, OEMs can ensure that their equipment boasts unmatched durability. This makes the equipment robust enough to withstand rigorous use.

Versatility: Welding allows OEMs to join metal stampings to create unique and versatile components. Whether it’s specialized enclosures for electronics or heavy-duty machinery components, welding ensures that OEMs can meet the diverse needs of their clients.

The medical industry demands precision and reliability, and the combination of metal stamping and welding offers:

High-Precision Components: Robotic welding paired with metal stamping produces intricate medical device components for surgical instruments and diagnostic equipment. This precision ensures that medical professionals can rely on these instruments for accurate and consistent results.

Clean Aesthetics: MIG and TIG welding are employed in the manufacturing of medical instruments. These methods produce clean, visually appealing welds, which is vital in medical settings where hygiene and appearance are paramount.

Aerospace manufacturers require the highest standards of quality, and welding complements metal stampings by:

Aircraft Components: Welding, especially robotic welding, ensures the creation of aircraft components that meet the stringent standards of the aerospace industry. This includes components like aircraft frames and engine parts, where precision and consistency are non-negotiable.

Lightweight Solutions: Aerospace manufacturers often use welding to join lightweight materials, ensuring that the aircraft remains fuel-efficient and capable of delivering optimal performance.

The electrical industry benefits from the combination of metal stamping and welding through:

Protection and Enclosures: Electrical manufacturers often require custom enclosures for sensitive electronic equipment. Welding methods like MIG and TIG welding help create precise and sturdy enclosures, protecting the equipment from environmental factors and ensuring its longevity.

By integrating these welding options with our metal stamping expertise, Dayton Rogers offers you a comprehensive and efficient solution that elevates the quality and functionality of your products. Trust us to meet your metal stamping and welding needs while keeping your production processes streamlined.

Laser cutting is ideal for low-to-medium volumes (prototypes up to ~5,000 parts) because it requires no hard tooling, offering significant upfront cost savings. Metal stamping (Progressive or Modular) becomes more cost-effective as volumes increase, as the piece-part price drops significantly to offset the initial tooling investment.

We utilize Turret Fabrication and Laser Cutting to produce prototypes and short runs with little to no tooling costs. Our turret systems allow for rapid tool changes and complex forming in a single setup, while our automated lasers (2k–4k watts) run “lights-out” for fast, efficient production of precision blanks.

While capacity varies by part geometry and tonnage, our standard precision press brake operations typically handle material thicknesses up to 0.50″ to 0.75″ (12mm to 19mm). For specific high-tonnage or large-format bending requirements, please consult our engineering team or the Red Book design guide.

Welding fabrication (MIG, TIG, Robotic, or Spot) is best for complex, multi-component parts where creating a single complex die is cost-prohibitive or impossible. It is also ideal for joining low-volume structural components. We often combine stamped components with robotic welding to offer a cost-effective hybrid solution for mid-to-high volume assemblies.

Yes. Unlike many job shops, Dayton Rogers specializes in custom fabricated fasteners and can modify standard hardware to meet specific project needs. This ensures a perfect fit for your assemblies without forcing you to rely on off-the-shelf constraints.

METAL FABRICATION NEAR MINNEAPOLIS, MN

8401 West 35W Service Drive

Minneapolis, MN 55449

METAL FABRICATION NEAR COLUMBUS, OH

2309 McGaw Road West

Columbus, OH 43207

METAL FABRICATION NEAR ARLINGTON, TEXAS

12223 C R Koon Hwy

Newberry, SC 29108

METAL FABRICATION NEAR ARLINGTON, TEXAS

1107 Commercial Blvd N

Arlington, TX 76001

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved