Posted: Feb 4, 2019

Distortions are sometimes unavoidable while metalforming, but if youre you are encountering fractures in your metalforming pieces, there are a few steps you can take to prevent them.

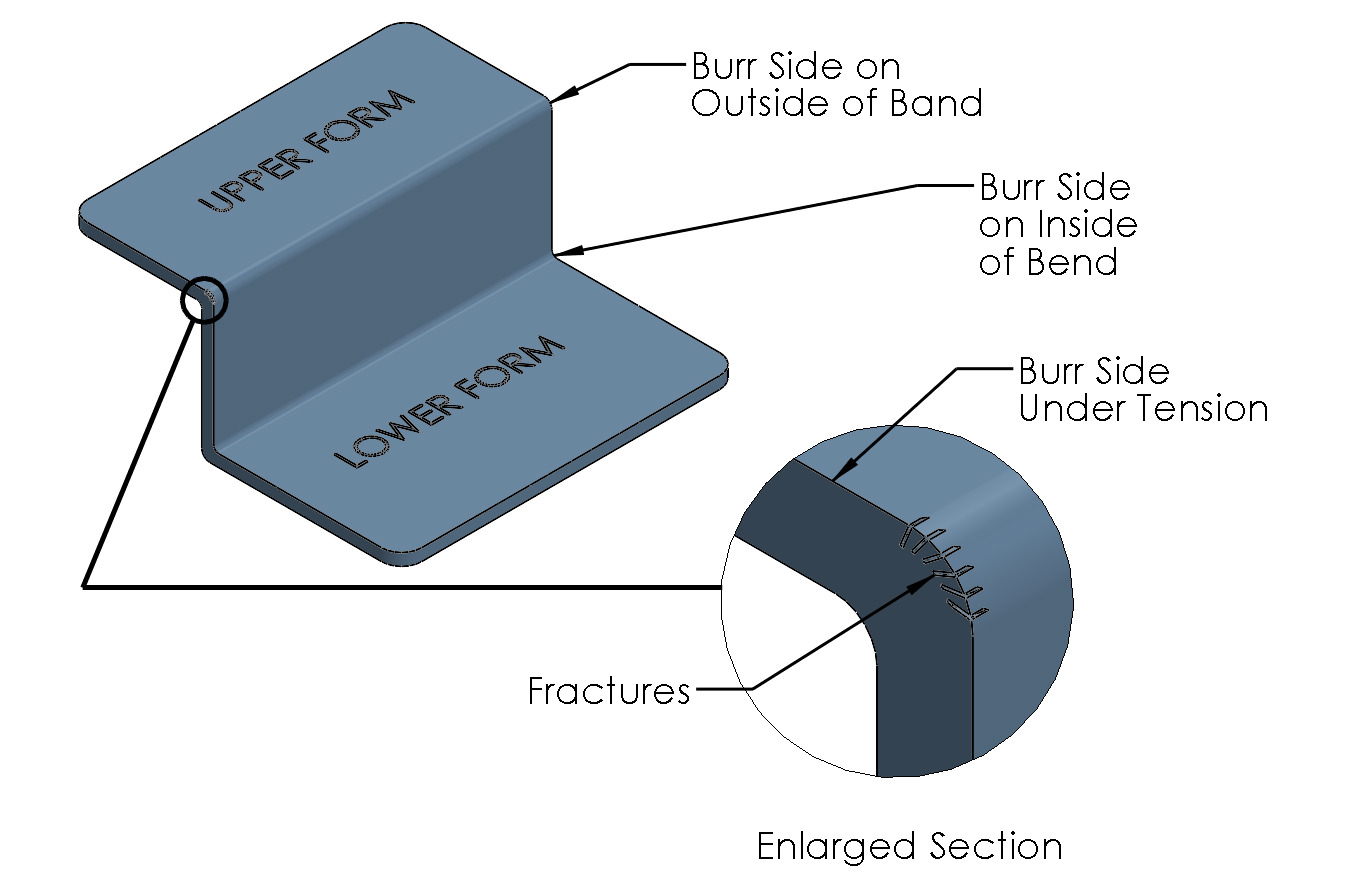

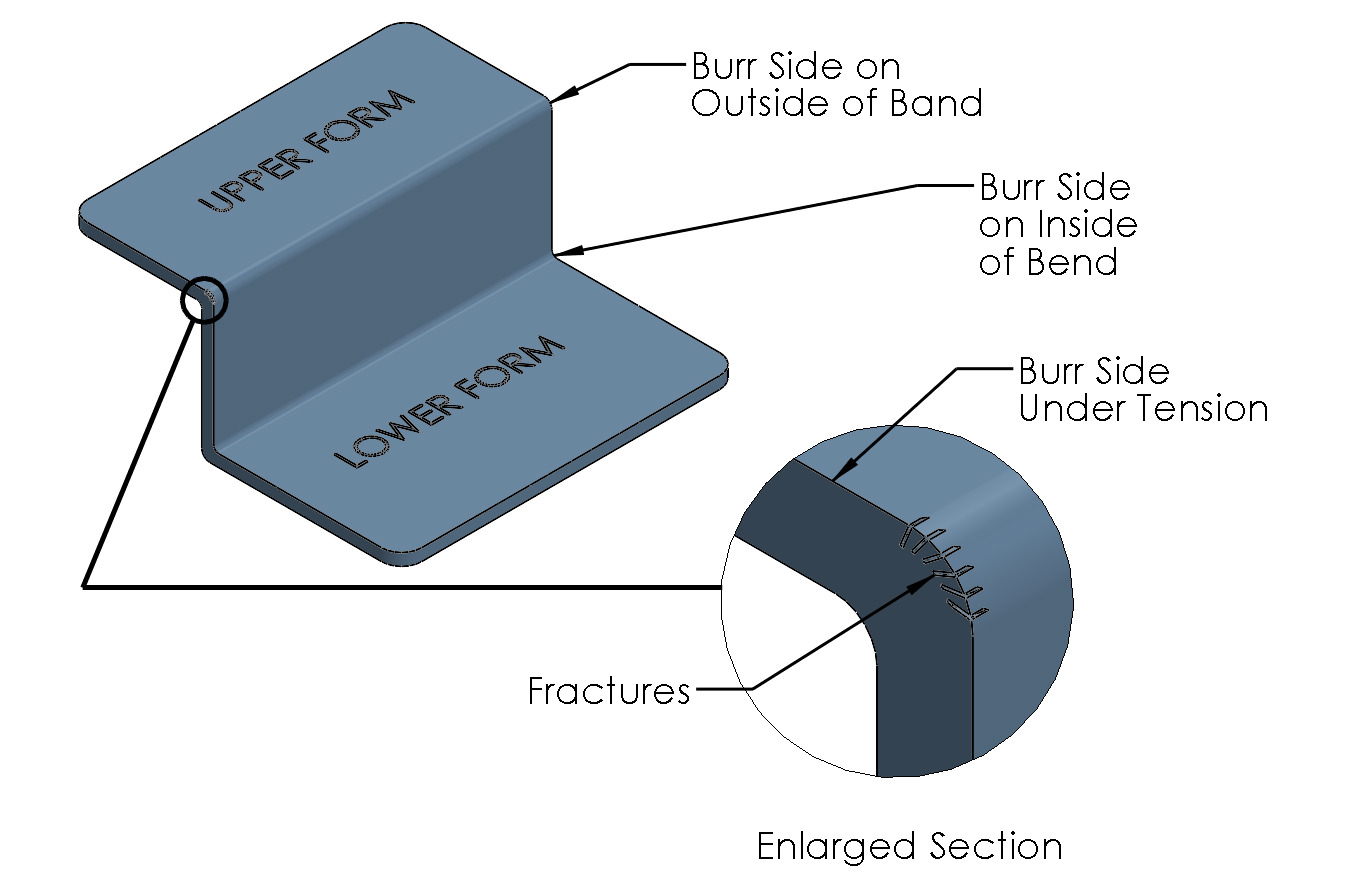

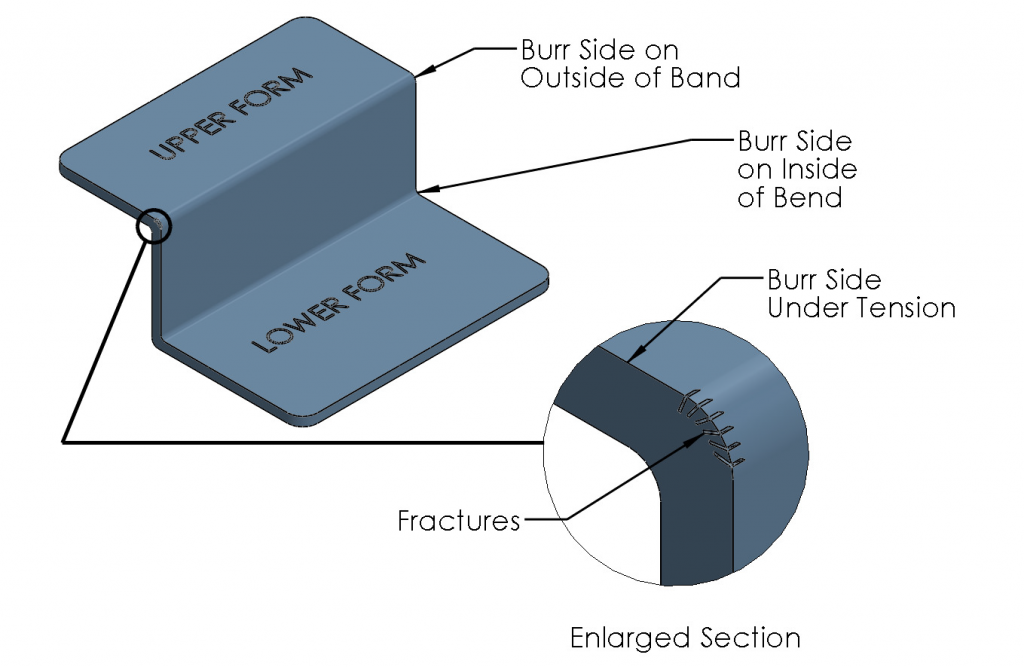

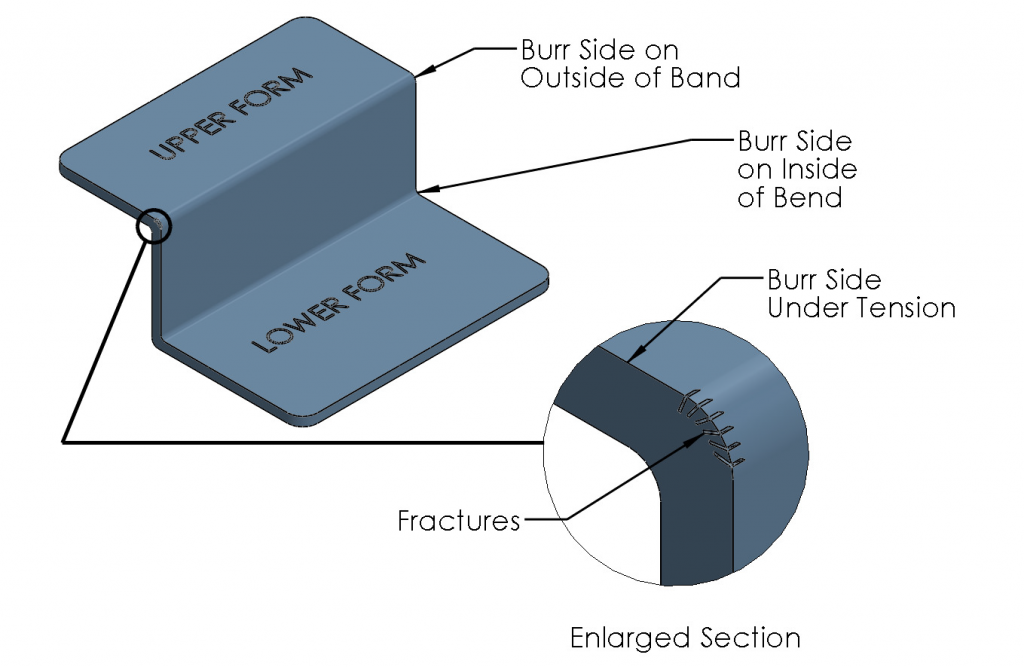

The illustration below shows a fracture condition that occurs when the burr side of the blank is on the outside of the bend.

This fracture condition occurs because the burr side of the blank on the outside of the bend is under tension. This causes the minute fractures on the sharp edge to open up and in extreme cases become visible.

Blanks should be produced so the burr side will be on the inside of the bend which is under compression like the lower form. However, when print requirements prevent this, or when a bend is in an opposite direction, like the upper form, fractures may occur.

Tumbling or deburring before forming can minimize the fractures in most cases. On extra heavy material with a very sharp inside bend radius, or on materials difficult to form, like SAE4130, tumbling before forming may not be adequate. It may be necessary to hand file or disc sand a radius on the sharp edges. Such secondary operations will add to the cost of production.

Therefore, for the most economical production and if design will permit, ample inside bend radii should be permitted for heavy and difficult forming material when the burr side of the blank must be on the outside of the bend.

If slight fractures are permissible, it should be indicated on the print or inquiry.

Want more metalforming and metal fabrication tips? Get your FREE copy of the signature Dayton Rogers Red Book (2018 Metalforming Design Handbook: Cost Effective Design Principles). This powerful book is your resource for all things metalforming and stamping.

Dayton Rogers is your trusted resource for sheet metal fabrication, metal stamps, metalforming and all your manufacturing company needs. Get a free quote today on your custom metal fabrication project.