Practical Tolerances for Short Run Metal Stampings

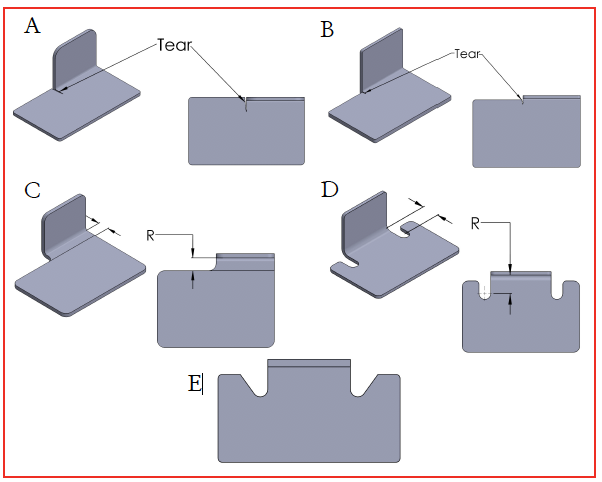

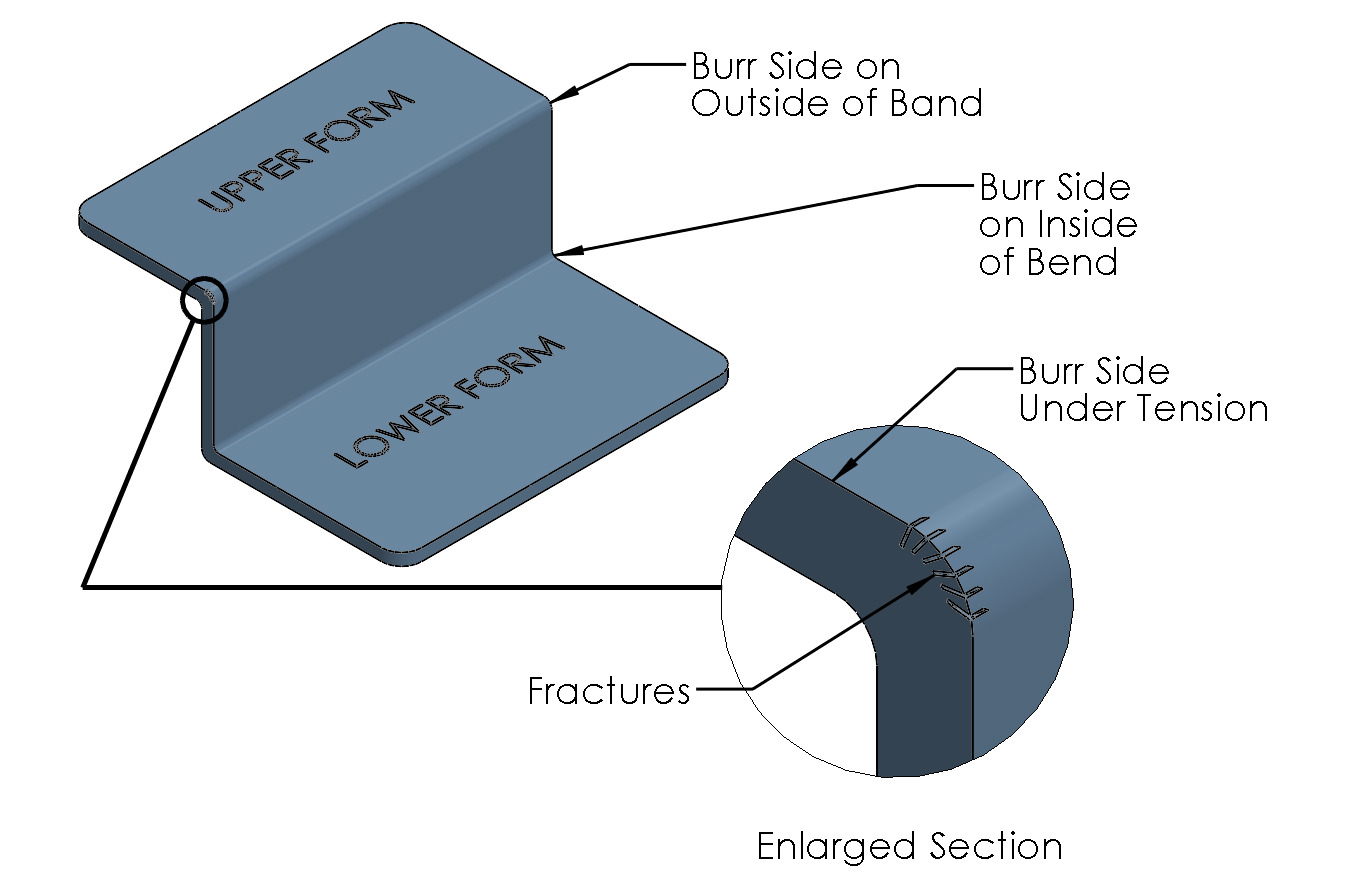

Practical tolerances for our Short Run Metal Stampings vary according to the design of the part. Generally, all dimensional tolerances compared to costs can be illustrated by the following diagram “A”. Reading from right to left, we illustrate that within the more generous limitations, the cost increases slowly—but, as the permissible variance is reduced, the … Practical Tolerances for Short Run Metal Stampings