Posted: Aug 5, 2019

Practical experience has proven that dimensioning and measuring practices must both be understood and agreed on by all parties to achieve a workable, mutual standard.

Formed sheet metal parts present a unique problem in that angular tolerances as well as the flatness conditions interact with single plane dimensions because of the flexibility of sheet metal, especially the thinner gauges. To achieve consistent results when measuring formed parts, a standard has to be established on where and how dimensions are to be taken.

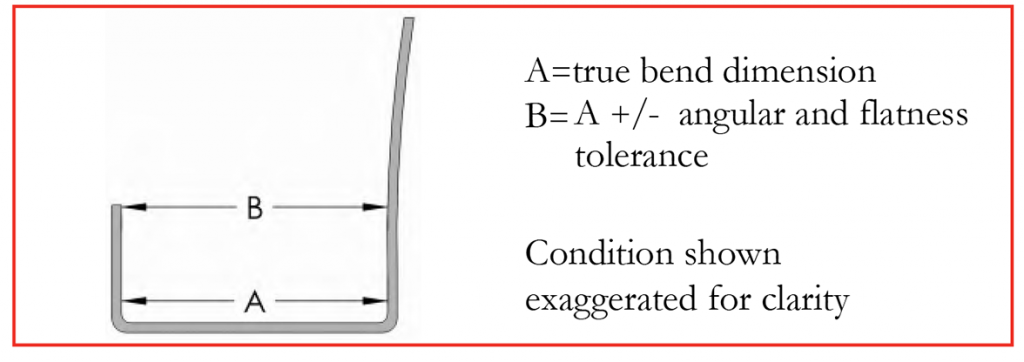

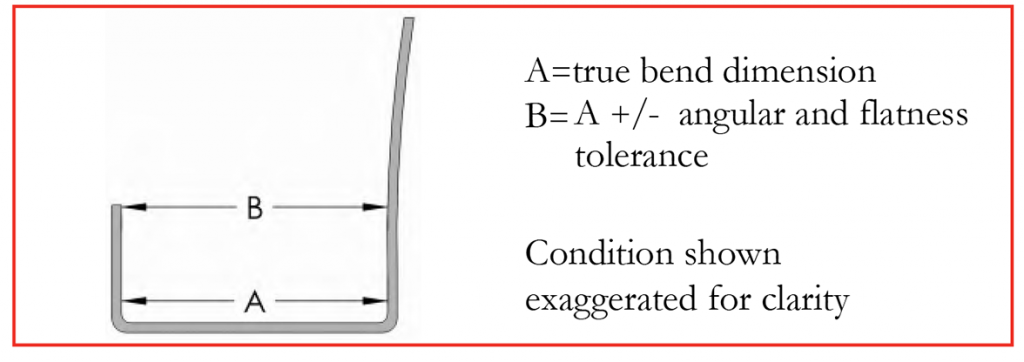

Form dimensions should be measured immediately adjacent to the bend radius in order not to include any angular and flatness discrepancy. See illustration below.

Feature-to-feature dimensions on formed legs of any length on flexible parts will be assumed to be measured in constrained condition, holding the part fixtured to the prints’ angularity specification. This standard is appropriate for the majority of thin sheet metal parts and results in a functional product. This is always true when the assembled part is, by design, held in constrained condition.

For the most economical production, dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to control tolerance accumulation.

It is generally recommended that dimensioning be done from a feature to an edge. Feature-to-feature dimensions in two planes should be avoided. Feature-to bend dimensions may require special fixtures or gauging.

This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles, while very appropriate for others.

Want more metalforming and metal fabrication tips? Get your FREE copy of the original Dayton Rogers Red Book. This powerful book is your resource for all things metalforming and stamping.

Dayton Rogers is your trusted resource for sheet metal fabrication, metal stamps, metalforming and all your manufacturing company needs. Get a free quote today on your custom metal fabrication project.

LOCATIONS