In our last blog, we dove into the sixth chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter Six taught us about punched holes. Now, join us as we take a closer look at extruded holes in Chapter Thirteen! Elements of Formed Stampings … The Red Book at a Glance: Formed Stamping

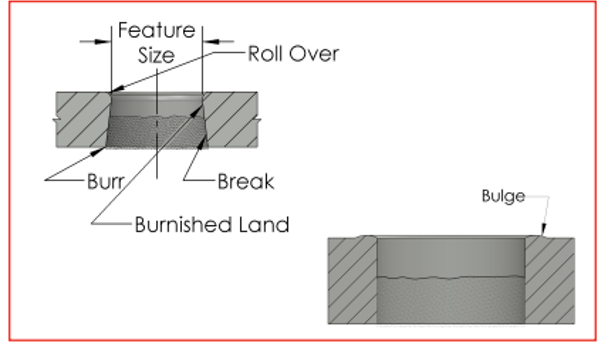

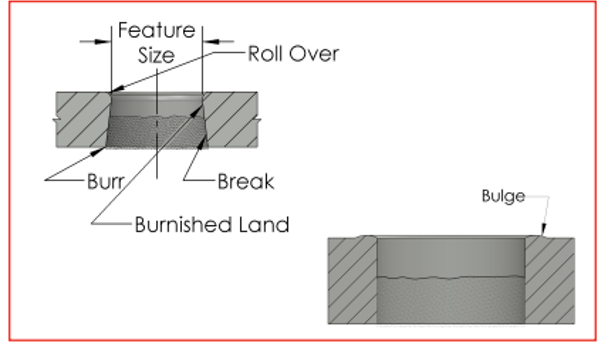

Definition of Punched Holes Identification of these punched holes can provide the basis for determining the inspection parameters. Roll-over is the natural consequence of the punching process, the mechanical properties of the material being punched, and the die application of techniques employed. Specification and Measurement of Punched Holes Dimension feature size limits only. Feature size … The Red Book at a Glance: Punched Holes

In our last blog, we dove into the forth chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter Four taught us about blank design. Now, join us as we take a closer look at piercing round holes in Chapter Five! To pierce holes … The Red Book at a Glance: Piercing Round Holes

In our last blog, we dove into the third chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter Three taught us about edge conditions. Now, join us as we take a closer look at blank designs in Chapter Four! A blanking die produces a … The Red Book at a Glance: Blank Design

In our last blog, we dove into the second chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter Two taught us about tolerances and how they vary for Short Run Metal Stampings according to the part’s design. Now, join us as we … The Red Book at a Glance: Edge Conditions

Think back to a year ago. As the pandemic made its way into the United States and other countries worldwide, consumers were panic buying due to the scarcity of products and fear of the unknown. Today, on the flip side, companies are the ones furiously trying to stock up to relieve anxieties and regain control. … Dayton Rogers Combats Price Increases in Manufacturing

In our last blog, we dove into the first chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter One taught us how to use short-run stampings and compared the process to typical fabrication methods in terms of technique and price. Now, join … The Red Book at a Glance: Tolerances

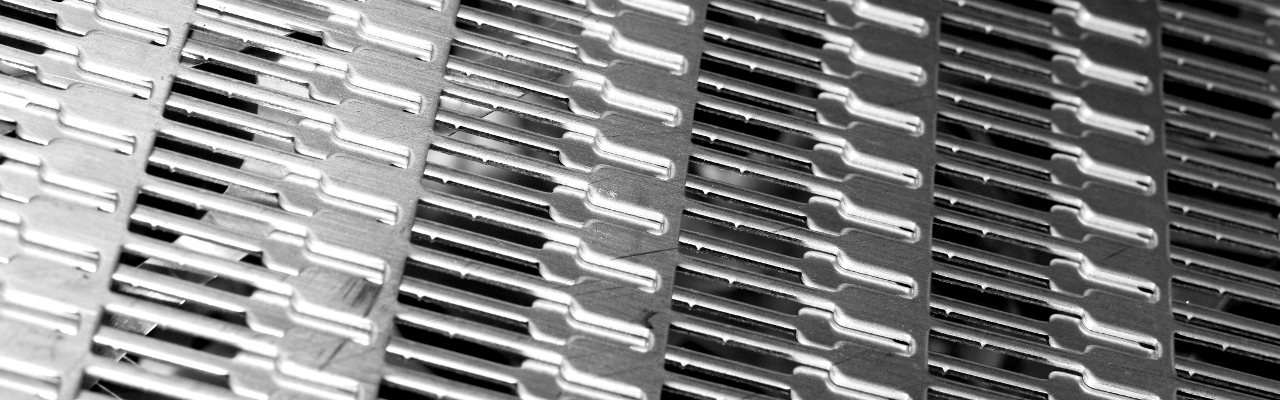

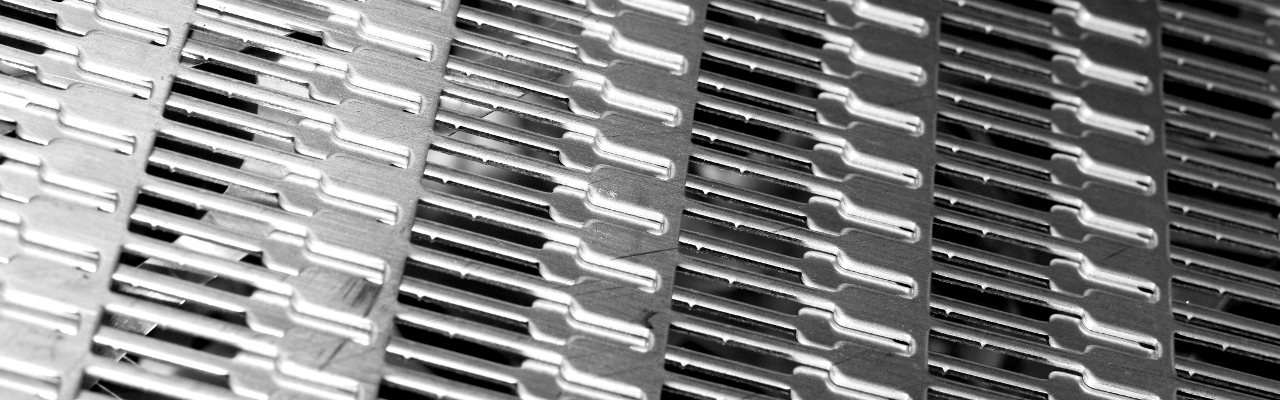

Metal stamping has been a critical component of the manufacturing industry since the industrial revolution. In fact, one of its earliest use cases was in Germany to produce frames and handlebars for bicycles. Since then, it has evolved into an essential part of the production of parts and components for a wide variety of industries … Metal Stamping 101: How It Works & Types

When it comes to metal manufacturing services, a single line of purchasing for fabrication needs is ideal for a variety of reasons. Instead of having to go to multiple businesses, you can just go to one location for all your needs. Deciding to outsource multiple manufacturing services from a single shop is much like shopping … Benefits of a Manufacturer with a Broad Service Offering