Principles of Design for Metal Stamping Metal Stamping Manufacturing Explained If you’re not yet familiar with the manufacturing method known as metal stamping, you’ve come to the right place to learn! Dayton Rogers pioneered the practice of short run metal stampings back in 1929, and we have now been in the metal stamping industry for … Principles of Design for Metal Stamping

Why Choose Custom Metal Fabrication? It’s no secret that Dayton Rogers is the grandfather of metal stamping. Although metal stamping is our process of choice as it is an incredibly versatile metal forming method, there is no one single process that can truly do it all. Dayton Rogers is dedicated to serving as your one … Add Value and Save Costs with Dayton Rogers’ Custom Metal Fabrication

Challenges of Precision Sheet Metal Fabrication In industries like aerospace, automotive, and electrical, it is imperative for components to be produced to spec. Even in cases where tolerances are extremely tight, any slight deviation from the outlined parameters can be detrimental to the function of the overall completed product. While it’s easy to understand why … High Precision Made Simple with Modular Stamping

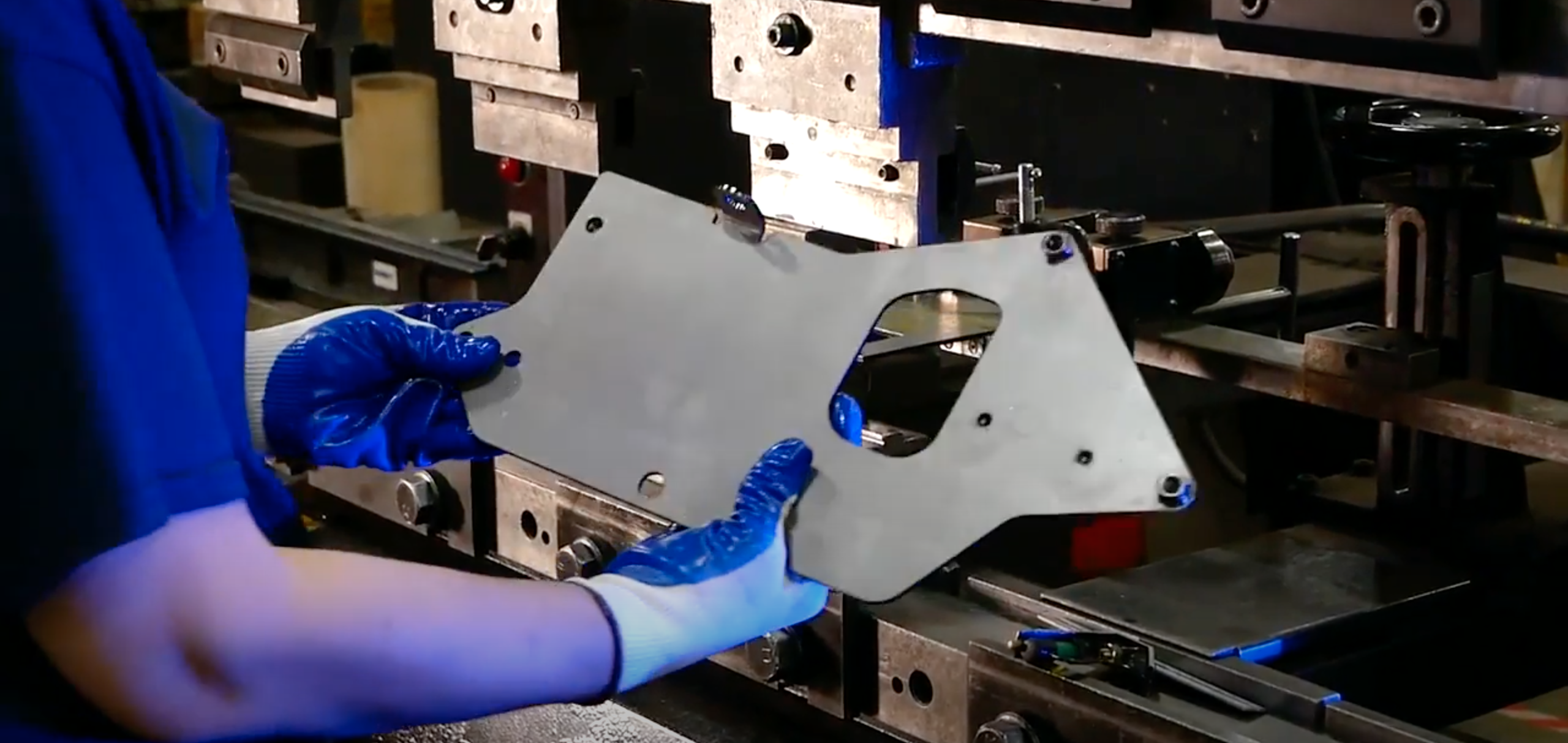

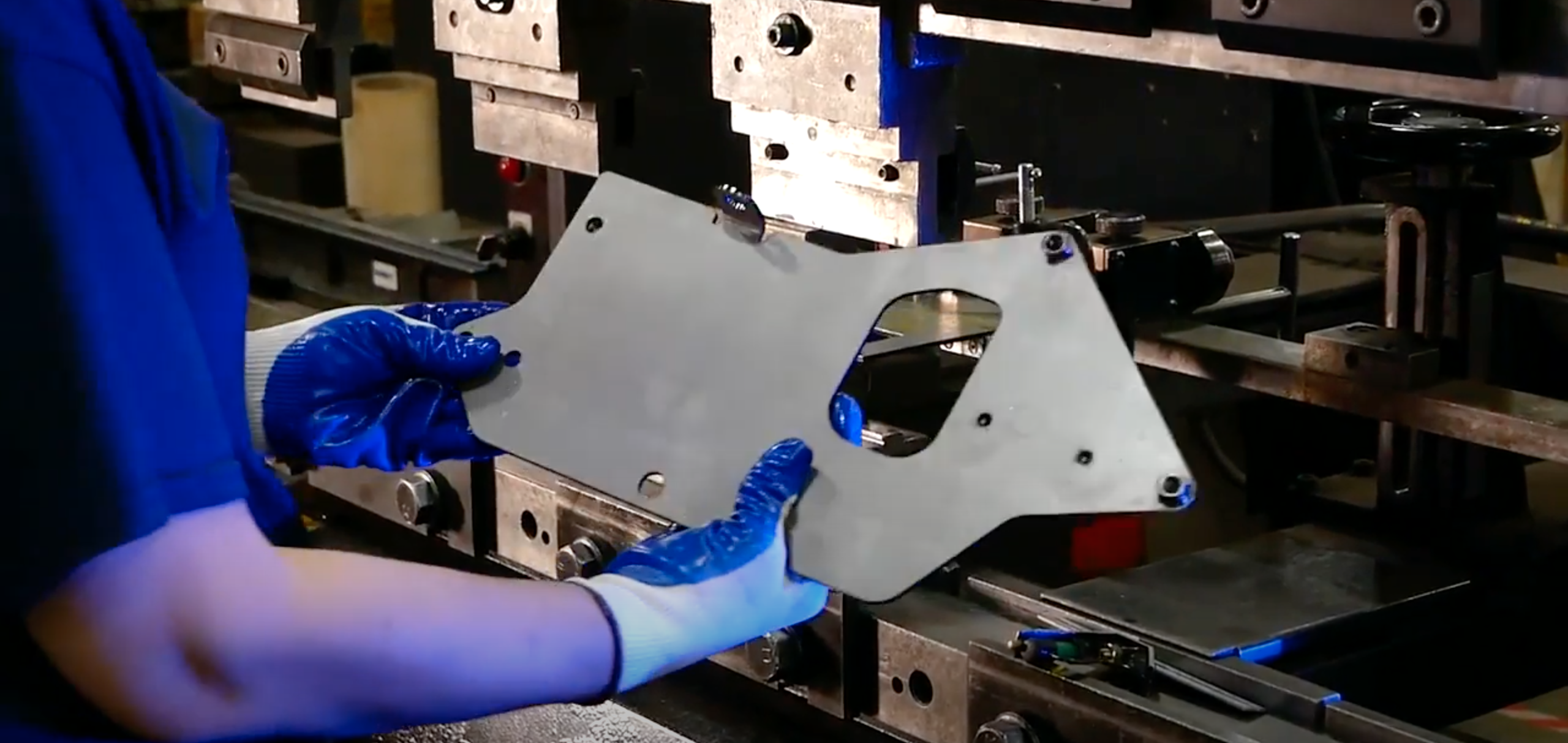

At Dayton Rogers, short run metal stampings are one of our key offerings. Short run metal stampings are just what they sound like: they are metal stamping projects with a low finished part volume. What quantity exactly qualifies as ‘short run’ depends on the metal stamper that you ask, but generally any order less than … 3 Types of Short Run Metal Stampings

You may be surprised to learn that we go beyond just metal stamping to serve as a one-stop shop for all of your sheet metal forming needs. Here at Dayton Rogers, we pride ourselves on being able to serve our customers with a wide range of custom metal manufacturing solutions including laser cutting and welding. … Custom Metal Manufacturing at Dayton Rogers

Metal stamping and fabrication are two distinct metalforming techniques used to create all kinds of products imaginable. From commonly used items like washers to high precision aerospace and medical parts, metal stamping and fabrication provide the range to do it all. Depending on your particular project requirements, one metal manufacturing method may be better than … What are Metal Stamping and Fabrication

Collaboration starts during our Discovery phase when not only is our Client learning about Dayton Rogers’ capabilities, superior service, pricing and, quality; but our sales and service team are learning about the needs and drivers for the Client project. Also, as part of this process, if desired, your assigned team of both technical and operational … The Dayton Rogers Difference: Discovery

Dayton Rogers created the mold when we pioneered the short-run metal stamping process. Since then, we have grown to be a full-service metal stamping and metal fabrication supplier. Trusted by leaders in all industries, we continue to be the go-to metalforming resource for every project with four manufacturing locations in the U.S. As pioneers in … <a href="https://news.daytonrogers.com/the-dayton-rogers-difference-pioneers-of-precision-metalforming">THE DAYTON ROGERS DIFFERENCE: PIONEERS OF PRECISION METALFORMING</a>

When designing metal blanks for precision metal stamping, there are a few guidelines to follow for the most economical results. Below, you’ll find some of these guidelines. These are tried-and-true best practices we’ve discovered in our over 90 years of metal stamping. GUIDELINES FOR BLANK DESIGN MINIMUM PRACTICAL SECTION THICKNESS Minimum practical section should never be less … Designing an Economical Blank for Precision Metal Stampings