Posted: Aug 26, 2021

In our last blog, we dove into the first chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter One taught us how to use short-run stampings and compared the process to typical fabrication methods in terms of technique and price.

Now, join us as we take a closer look at tolerances in Chapter Two!

Tolerances

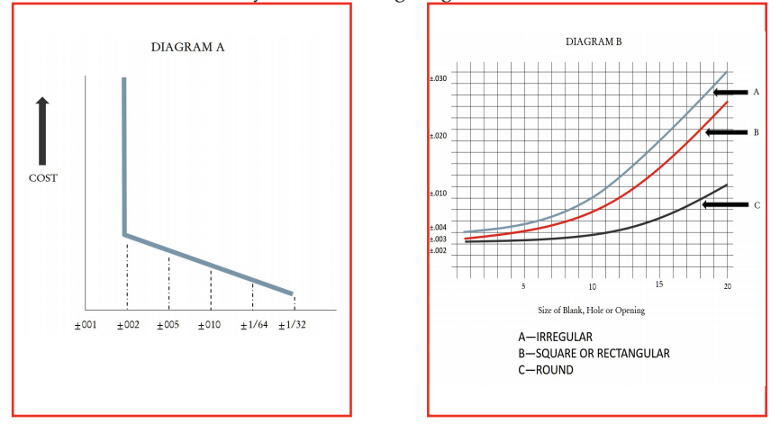

Practical tolerances for our Short Run Metal Stampings vary according to the design of the part. Generally, all dimensional tolerances compared to costs can be illustrated by the following diagram “A.”

In the diagrams above, we illustrate that within more generous limitations, the cost increases slowly. However, as the permissible variance reduces, the cost increases more rapidly. And, as limits are further reduced, the cost rises sharply to the extent that it might be impractical to stamp. Thus, there is a definite breakoff for stamping operations beyond which machining, grinding, lapping, honing, and other precision operations must be employed.

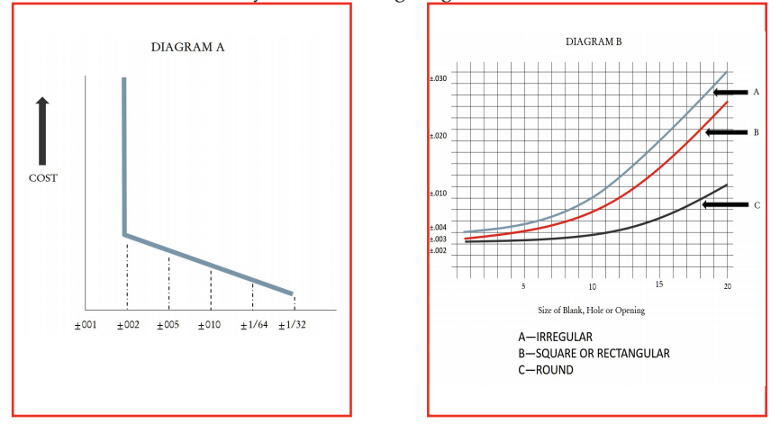

In diagram “B,” we indicate the relationship between tolerance and size for flats, holes, and openings in flat blanks for the most economical tools and production. These tolerances can be held on the die side of the part, as well as the punch side of the holes and openings. For the most economical tooling and production of related holes, the hole location is referred to as the dimension between holes, and hole location is determined from a centerline of the blank.

Using these interpretations, we can hold plus or minus .005 tolerance between hole centers with the lowest priced tooling. For plus or minus .002 tolerance between hole centers, slightly higher priced tooling would be used. In contrast, close hole locations measured to the blank contour could require expensive dies and additional operations.

Download the Red Book!

If you’re interested in reading the full version of the Metalforming Design Handbook, click the button below.