Are you considering a project, but are unsure if you should choose metal stamping or fabrication? This handy reference guide will break down the difference between these two methods and which you should choose for your project. WHAT IS METAL STAMPING? Metal stamping is the process of converting flat metal sheets into specific shapes. It encompasses … How to choose Between Metal Stamping and Metal Fabrication

Carbon steel is a popular choice for metal forming and metal stamping products for the wide variety of finishes and rigidity. When choosing a cold rolled carbon steel strip, it’s important to know what softness is best for your project. Below are the varieties of carbon steel strip you can choose for your project, and for which … How to Choose the Right Carbon Steel Strip for Metal Forming

Practical tolerances for our Short Run Metal Stampings vary according to the design of the part. Generally, all dimensional tolerances compared to costs can be illustrated by the following diagram “A”. Reading from right to left, we illustrate that within the more generous limitations, the cost increases slowly—but, as the permissible variance is reduced, the … Practical Tolerances for Short Run Metal Stampings

Practical experience has proven that dimensioning and measuring practices must both be understood and agreed on by all parties to achieve a workable, mutual standard. Formed sheet metal parts present a unique problem in that angular tolerances as well as the flatness conditions interact with single plane dimensions because of the flexibility of sheet metal, … Dimensioning Practices for Press Brake

The Tonnage Formula is the pressure required in tons to cut a blank or contour using a flat faced punch with no shear. Tonnages can be calculated for forming, bending, cutting, drawing, and blanking operations. Having the ability to calculate the tonnages for a sheet metal project is vital for the completion and success of … How to Calculate Tonnage [FREE FORMULA]

When working with aluminum over sheet metal, several variables need to be considered. Aluminum is typically thicker and stronger, and requires more force to bend as well as consideration of edge conditions and punch nose radii. This free chart outlines what bend radii is required for the approximate thickness of aluminum. We recommend printing it out to keep as … The Minimum Bend Radius for Aluminum

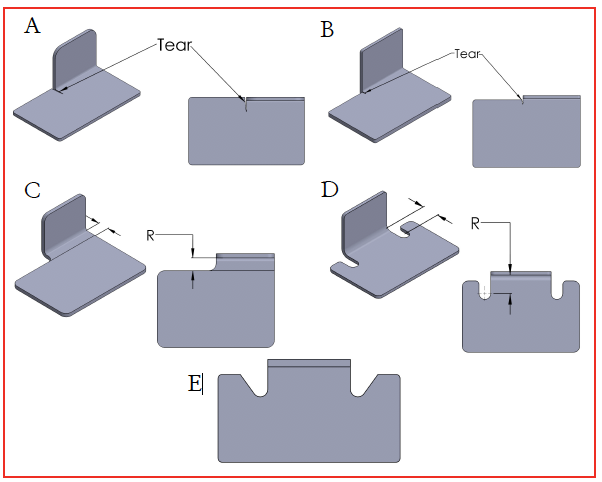

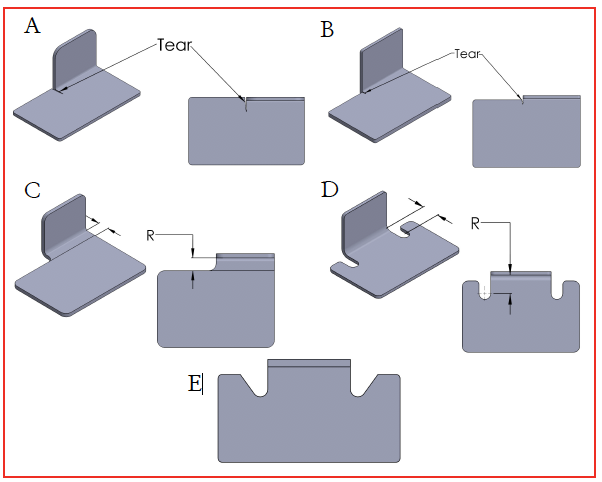

The position of the metal form is vital for the success of your project. Diagram “A” illustrates a design that is not desirable for quality or economy. When the form is inside the blank profile, as shown, the material must be torn through the stock thickness and the bend radius. If the part is under … How to Position the Metal Form

During shearing and punching, there are a number of factors to keep in mind to improve edge conditions. On ferrous materials, the clearance between punch and die should be about 8% to 10% of the material thickness, which may vary due to hardness and thickness. The punch and die clearance will differ on various non-ferrous … 3 Ways to Improve Edge Conditions

Many metal stampings require holes, but there are several considerations when choosing where to place a hole and how to pierce the hole. To pierce holes with economical tools and operations, the hole diameter must not be less than the stock thickness. If the hole diameter is less than the stock thickness (or less than … How to Pierce Round Holes in Metal Stampings

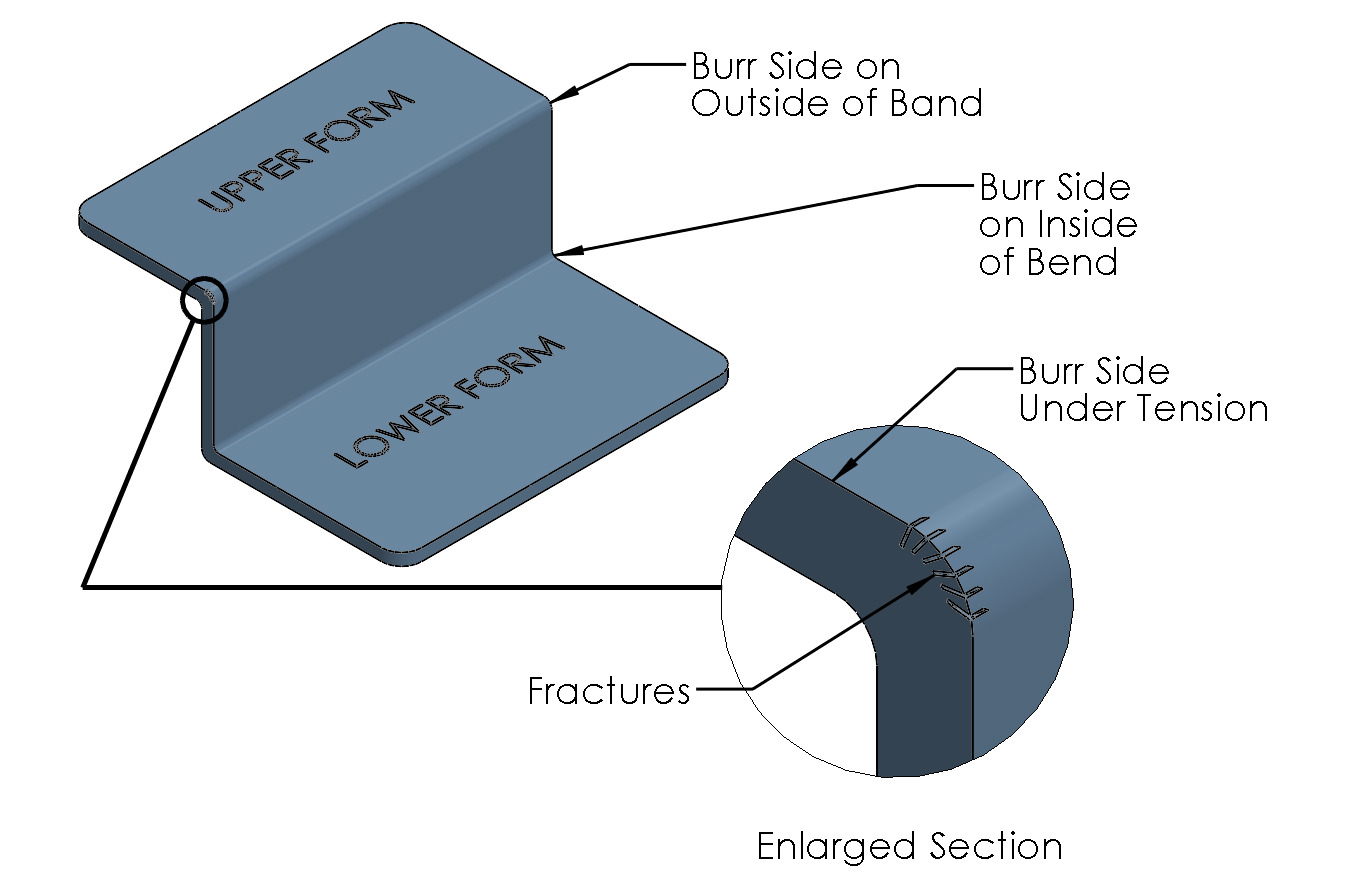

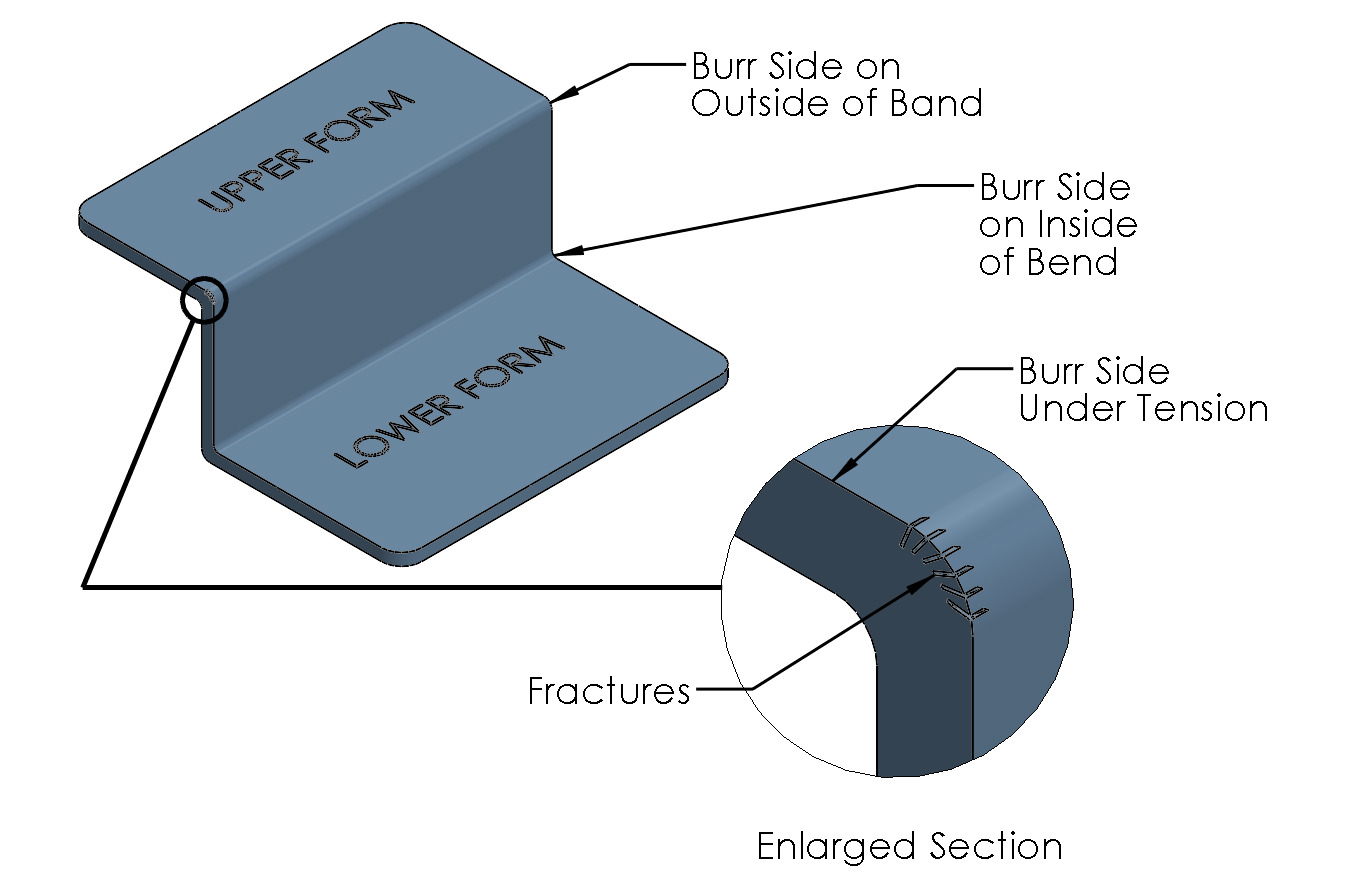

Distortions are sometimes unavoidable while metalforming, but if youre you are encountering fractures in your metalforming pieces, there are a few steps you can take to prevent them. The illustration below shows a fracture condition that occurs when the burr side of the blank is on the outside of the bend. This fracture condition occurs … How to Prevent Fractures in Metalforming

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved