Live Webinar

Dayton Rogers Red Book Live Webinar w/ Mike Ingalls

Design Smarter. Stamp Faster. Save More.

Learn cost-saving metalforming design principles straight from the Dayton Rogers Red Book – “Metalforming Design Handbook-Cost Effective Design Principles”, also known as “The Original Red Book”. We’ll cover tolerance choices that control cost, hole sizing and spacing that prevent rework, forming fundamentals that protect strength, and when short-run stamping outperforms progressive, machining, or laser-plus-brake. Plus, bring your questions for a live Q&A with Mike Ingalls, Executive Director of Engineering & Development.

Event Details

Date: Wednesday, November 12, 2025

Time: 11:45 – 12:45 Central Time (US)

Where: Microsoft Teams (virtual)

Mike Ingalls

Executive Director of Engineering & Development

With over 8 years of leadership at Dayton Rogers, Mike brings deep expertise in metal stamping and fabrication, operations, and product development. He is passionate about helping engineers design smarter, stamp faster, and save more.

Connect on LinkedInWhat You’ll Learn.

Short-run stamping vs. progressive, machining, casting & laser.

Hole, web & edge rules that prevent distortion/rework.

Hole, web & edge rules that prevent distortion/rework.

Tolerance choices that control cost (±0.005″ vs. ±0.002″).

Forming fundamentals: bend radii, min leg heights, fatigue resistance.

Spec’ing burr & flatness to reduce finishing costs.

Live Q&A

Bring your toughest design questions!

During the webinar, Mike Ingalls will answer questions in real time — from tolerances and bend radii to when short-run stamping beats progressive or laser cutting.

Having trouble registering? Email L Matheis and we’ll get you set.

Get the Red Book

The Dayton Rogers Red Book is the industry’s trusted design guide for short-run metal stamping. Packed with real-world rules, diagrams, and cost-saving insights, it will help you design smarter parts, shorten production cycles, and improve quality.

“The Red Book transformed how our team approaches design for manufacturability.

Practical, straight-to-the-point guidance.”

How Deep Draw Metal Stamping Works

How Does Deep Draw Metal Stamping Work? Table of Contents Deep draw metal stamping is a fascinating and intricate manufacturing process used across various industries, including automotive, aerospace, and defense

Types of Tooling for Short Run Metal Stamping Explained

Types of Tooling for Short-Run Metal Stamping Explained Tool and die-making is an intense process that plays a key role in creating countless parts that are part of our everyday

The Ultimate Guide to Progressive Stamping

The Ultimate Guide to Progressive Stamping Here at Dayton Rogers, one the metal stamping processes we offer to our customers is progressive stamping. Progressive stamping involves feeding a strip of

THE RED BOOK AT A GLANCE: LASER CUTTING AND CONSIDERATIONS

In our last blog, we dove into Chapters 27 & 28 of the Metalforming Design Handbook, also known as the “Red Book.” Industry leaders recognize our “Red Book” as the go-to manual

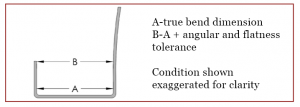

THE RED BOOK AT A GLANCE: DIMENSIONING PRACTICES

In our last blog, we dove into Chapters 25 & 26 of the Metalforming Design Handbook, also known as the “Red Book.” Industry leaders recognize our “Red Book” as the go-to manual

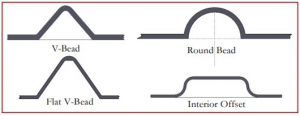

The Red Book at a Glance: Styles of Embossing

In our last blog, we dove into Chapter 13 of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming

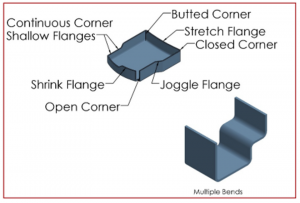

The Red Book at a Glance: Formed Stamping

In our last blog, we dove into the sixth chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal

The Red Book at a Glance: Punched Holes

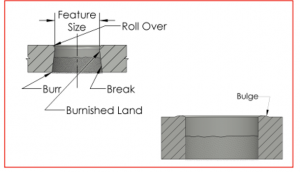

Definition of Punched Holes Identification of these punched holes can provide the basis for determining the inspection parameters. Roll-over is the natural consequence of the punching process, the mechanical properties

The Red Book at a Glance: Piercing Round Holes

In our last blog, we dove into the forth chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal

The Red Book at a Glance: Blank Design

In our last blog, we dove into the third chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal

The Red Book at a Glance: Edge Conditions

In our last blog, we dove into the second chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal

The Red Book at a Glance: Tolerances

In our last blog, we dove into the first chapter of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal