Collaboration starts during our Discovery phase when not only is our Client learning about Dayton Rogers’ capabilities, superior service, pricing and, quality; but our sales and service team are learning about the needs and drivers for the Client project. Also, as part of this process, if desired, your assigned team of both technical and operational … The Dayton Rogers Difference: Discovery

Dayton Rogers created the mold when we pioneered the short-run metal stamping process. Since then, we have grown to be a full-service metal stamping and metal fabrication supplier. Trusted by leaders in all industries, we continue to be the go-to metalforming resource for every project with four manufacturing locations in the U.S. As pioneers in … <a href="https://news.daytonrogers.com/the-dayton-rogers-difference-pioneers-of-precision-metalforming">THE DAYTON ROGERS DIFFERENCE: PIONEERS OF PRECISION METALFORMING</a>

When designing metal blanks for precision metal stamping, there are a few guidelines to follow for the most economical results. Below, you’ll find some of these guidelines. These are tried-and-true best practices we’ve discovered in our over 90 years of metal stamping. GUIDELINES FOR BLANK DESIGN MINIMUM PRACTICAL SECTION THICKNESS Minimum practical section should never be less … Designing an Economical Blank for Precision Metal Stampings

During the last week of August 2022, David Fenske, CEO of Dayton Rogers participated in the Be the Change Golf Tournament to raise funds for programs involving employment for “second chance” individuals. Dayton Rogers is proud of our involvement to train and develop employees at all stages! His interview captured with CBS Minnesota highlights Dayton … In The News SEPT 2022

Lasers are a popular choice for short-run stampings or more precise parts. While lasers in many ways make manufacturing simpler, there are some unique considerations you need to make before designing a part for laser cutting. In addition to production economics, precision, and edge condition, consider these characteristics of laser-produced parts in your design process: 1. … 4 Key Considerations When Designing for Laser Cutting

In our last blog, we dove into Chapters 27 & 28 of the Metalforming Design Handbook, also known as the “Red Book.” Industry leaders recognize our “Red Book” as the go-to manual for precision metal forming practices. Chapters 27 & 28 taught us about the dimensioning practices for turret press and press brakes. Now, join us as we … THE RED BOOK AT A GLANCE: LASER CUTTING AND CONSIDERATIONS

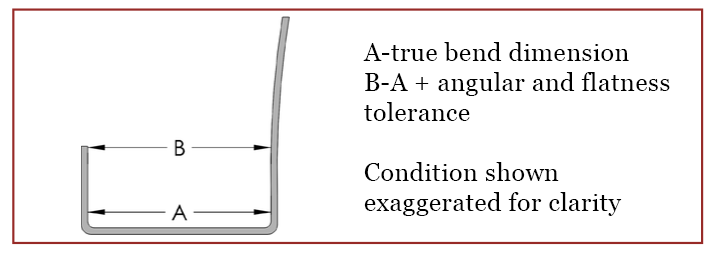

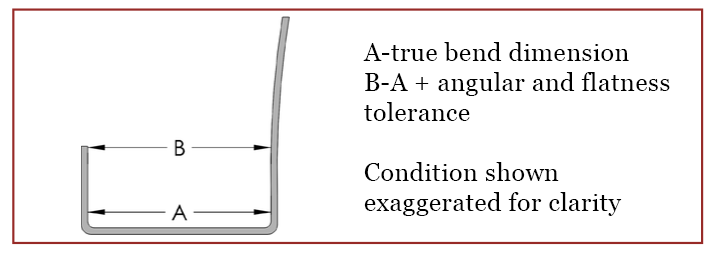

In our last blog, we dove into Chapters 25 & 26 of the Metalforming Design Handbook, also known as the “Red Book.” Industry leaders recognize our “Red Book” as the go-to manual for precision metal forming practices. Chapters 25 & 26 taught us about the measurement and limits of burrs and flatness. Now, join us as we take a … THE RED BOOK AT A GLANCE: DIMENSIONING PRACTICES

May 2, 2022 – The Dayton Rogers team is excited to announce that their new corporate website is set to launch the first week of May 2022. The process of designing and developing the new website began in Q4 2021, when Dayton Rogers leadership saw an opportunity to better support customers through an improved website … Dayton Rogers Adds Value for Customers Through Launch of New Website

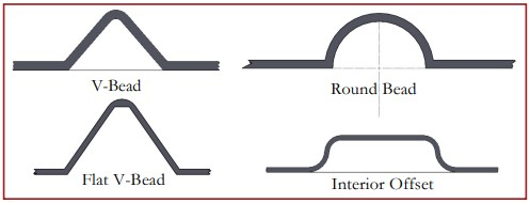

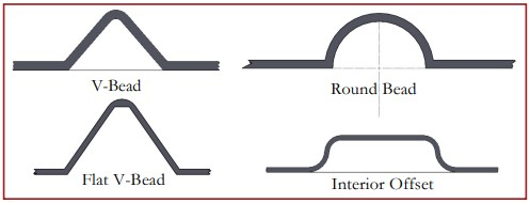

In our last blog, we dove into Chapter 13 of the Metalforming Design Handbook, also known as the “Red Book,” which industry leaders recognize as the go-to manual for precision metal forming practices. Chapter 13 taught us about punched holes. Now, join us as we take a closer look at styles of embossing in Chapter 19! Styles of Embossing Specification … The Red Book at a Glance: Styles of Embossing