The fast-paced world of motorsports elicits unparalleled levels of excitement from fans, participants, and engineers alike. There is truly no other venture pursued by manufacturers and fabricators the world over that gets people’s hearts racing the same way that racing itself does.

Performance vehicle builds are some of the most meticulously planned machines in the automotive industry, embodying the peak of what the engineering team and the vehicle itself are both capable of.

These performance builds for motorsports call for the most reliable metal parts and components available. These precision parts are often highly customized to provide precisely tailored solutions that are unique to each vehicle.

For this reason, engineers in motorsports need a manufacturing and automotive fabrication partner that they can count on to deliver high quality parts on-time, even when faced with exacting requirements and the most stringent of deadlines.

Dayton Rogers is proud to be that partner to the motorsports sector, thanks to our short run metal stamping and automotive fabrication capabilities.

The Art of Short Run Metal Stamping

In the world of motorsports, metal stamping is an invaluable manufacturing process thanks to the low tooling costs and short lead times that make rapid prototyping and quick delivery a breeze

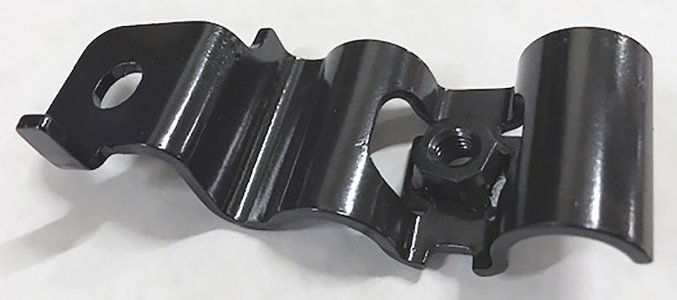

While metal stamping for the automotive sector may conjure imagery of large body panels and framework, Dayton Rogers places an emphasis on the often overlooked small scale parts that go into performance vehicles for motorsports. Our expertise in short run metal stamping allows us to design, prototype, and manufacture a wide variety of automotive parts that are engineered for performance, including: exhaust covers, mounting brackets, hinges, safety components, accessories, and more for consumer aftermarket automotive kits and performance engineering teams alike.

Although the impact of these parts may seem negligible on a surface level, the truth is that the quality of every single vehicle component counts toward placing on the podium in motorsports. Dayton Rogers’ focus on these smaller metal stamped parts allows us to take a more tailored approach to meet the specific needs of performance racing vehicles with premium materials and tight manufacturing tolerances. Here are just a few of the metal stamped parts that we offer to bolster performance and safety in racing vehicles.

Exhaust covers, also known as heat shields, provide thermal protection to components surrounding the exhaust pipes in performance vehicles. The extreme exhaust temperatures in high level motorsports pose a risk of damaging surrounding equipment and create additional hazards that threaten driver safety. Dayton Rogers can produce metal stamped exhaust covers out of a variety of metals to achieve the most effective temperature insulation for your vehicle

In the hypercompetitive world of motorsports, every opportunity for weight reduction is critical to increasing vehicle performance. Dayton Rogers produces metal stamped mounting brackets and hinges out of lightweight metals that enhance efficiency but don’t sacrifice durability. Whether you need brackets for digital dashboard mounting systems or hinges for lightweight carbon fiber panels, you can count on Dayton Rogers to deliver.

The cockpit provides further opportunities for weight reduction; however, it is imperative to prioritize driver safety inside the vehicle above all else. Durable components that minimize the risk of harm to the driver should be employed wherever possible, especially in the cockpit. Dayton Rogers produces buckles, fasteners, and inertia reels for seat belts and safety harnesses that keep the driver safely secured in their place. We also provide rigid brackets, gussets, and suspension mountings for roll cages, which support the structure of the cockpit even in the case of high speed impact.

Although metal stamping is Dayton Rogers’ primary manufacturing method, some projects require additional refinement, joining, and assembly once they’ve come off the press. To expedite the manufacturing process and provide the greatest value to our customers, Dayton Rogers offers additional automotive fabrication solutions including TIG welding, CNC machining, and parts assembly.

By offering these additional automotive fabrication methods under one roof, Dayton Rogers can slash lead times that would otherwise be spent transporting parts from shop to shop. In an era where supply chain management is crucial for maintaining on-time deliveries and part affordability, we’re proud to give our customers the advantage of a manufacturer with our secondary fabrication capabilities.

When employed wisely, metal stamping can be combined with welding and fabrication in a motorsports project to increase part quality, minimize scrap, and reduce manufacturing costs overall.

Our engineering team specializes in design for manufacturability, or DFM. This allows our customers to bring us their proposed part design and required tolerances, then have our team analyze the design for opportunities to increase manufacturability and cost effectiveness.

Some designs are simplified by employing welding and fabrication into the creation of the finished part. very complex part that would be expensive to produce can be brought down to a much lower cost with a shorter lead time by our DFM engineers.

Dayton Rogers has led the metal forming industry for more than 90 years, using metal stamping, welding, and fabrication expertise to create a wide array of parts for multiple applications. Our metal stamping and automotive fabrication services create unique solutions that are integral to your motorsports project’s success. If you’re ready to discuss our available metal forming methods in a consultation at no cost to you, don’t wait. Call today to speak to one of our metal forming experts about your next automotive project or schedule an in-person meeting.

Want to learn more about metal stamping and fabrication? Get your FREE copy of the Design Principles Red Book. This Design Principles booklet describes the various common conditions that occur in the fabrication of parts.

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved