Metal stamping is a versatile style of metal forming that can be strategically utilized to minimize production time, bring down manufacturing costs, and ensure part repeatability across a range of industries. One such sector that benefits from the perks of metal stamping is the firearms industry, where precision is never compromised, and performance is always paramount.

At Dayton Rogers, we have a history of serving the United States Military, sporting goods companies, and other firearms manufacturers. We proudly provide a metal forming solution that delivers on speed and quality without breaking any budgets. With our manufacturing capabilities in progressive stamping, modular stamping, and deep draw stamping, we can create a variety of components that guarantee precision and prioritize safety in the firearms industry.

Metal stamping has revolutionized the production of firearms in several ways, making it an essential process in the industry. Thanks to this cost-effective, quality manufacturing solution, the firearms industry has rapidly advanced the way that firearms are made.

One of the main advantages of metal stamping in the firearms industry is its ability to produce precise and consistent components. The use of specialized machinery and tools ensures that each part is shaped accurately and uniformly. This is crucial in the production of firearms, as even the slightest deviation in size or shape can affect the functionality and safety of the weapon.

Metal stamping is a cost-effective method of producing firearms components. The use of high-speed presses and automated processes allows for large-scale production at a lower cost. This is especially beneficial for manufacturers who need to produce a high volume of firearms to meet market demand.

Metal stamping allows for a wide range of design options when it comes to firearms components. The use of different dies and punches allows for a wide degree of design customization in even the simplest parts. This versatility in design is crucial for manufacturers who need to produce a variety of firearms to cater to different needs, preferences, and specifications.

The use of high-speed presses and automated processes in metal stamping allows for faster production times. This is especially beneficial for manufacturers who need to meet tight deadlines or keep up with high market demand. The faster production time also translates to a quicker turnaround time for customers, making it a win-win situation for both manufacturers and consumers.

One type of metal stamping that is commonly used in the firearms industry is deep draw metal stamping. This process involves the use of a punch and die to create deep, hollow shapes in metal sheets or strips. This is achieved by pulling the metal into the die cavity, creating a seamless and uniform shape.

Progressive metal stamping is a type of metal stamping process that involves the use of a progressive die to create complex and precise components for the firearms industry. It allows for the simultaneous shaping and cutting of metal sheets or strips, resulting in faster production times and cost-effective manufacturing. This process is crucial in producing precision components such as triggers, firing pins, and magazine bodies, ensuring the functionality and safety of firearms.

Modular metal stamping is a type of metal stamping process that involves the use of modular tooling to create precision components for the firearms industry. It allows for the efficient production of complex and intricate parts by using interchangeable modules that can be easily swapped out to accommodate different designs. This method ensures consistent quality and reduces production time, making it an essential process in manufacturing precision components for firearms.

Need a part, but don’t know where to start?

Find your manufacturing match at Dayton Rogers today!

Dayton Rogers brings a wealth of metal forming expertise to the firearms industry, offering an array of meticulously crafted metal stamped parts. These components, each a testament to Dayton Rogers’ commitment to quality metal stampings, include the following:

Stability is the cornerstone of accurate shooting, and bipods play a pivotal role in providing the necessary support. Dayton Rogers’ metal stamping capabilities ensure the production of robust and reliable bipod components, contributing to enhanced firearm accuracy.

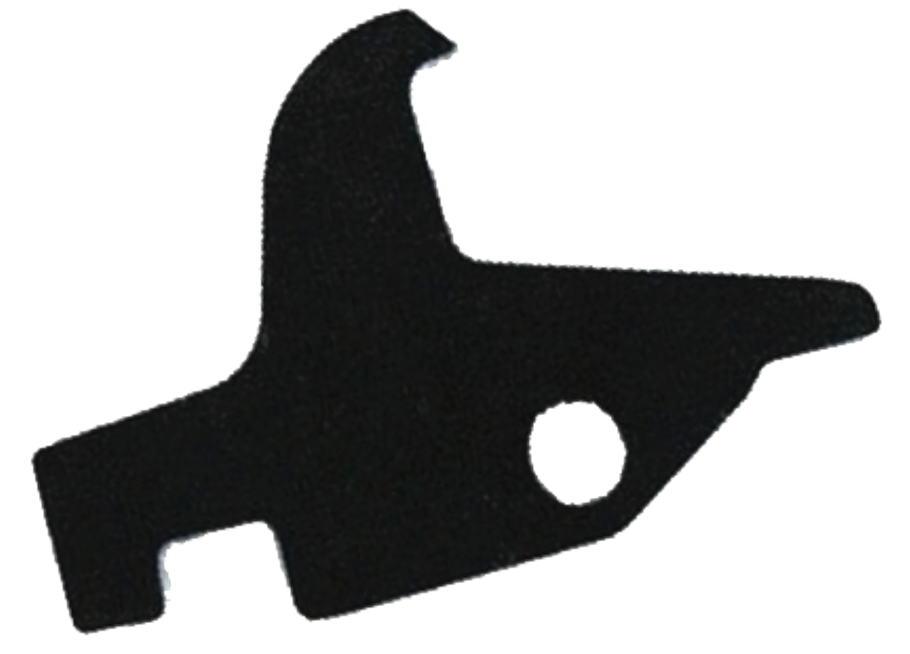

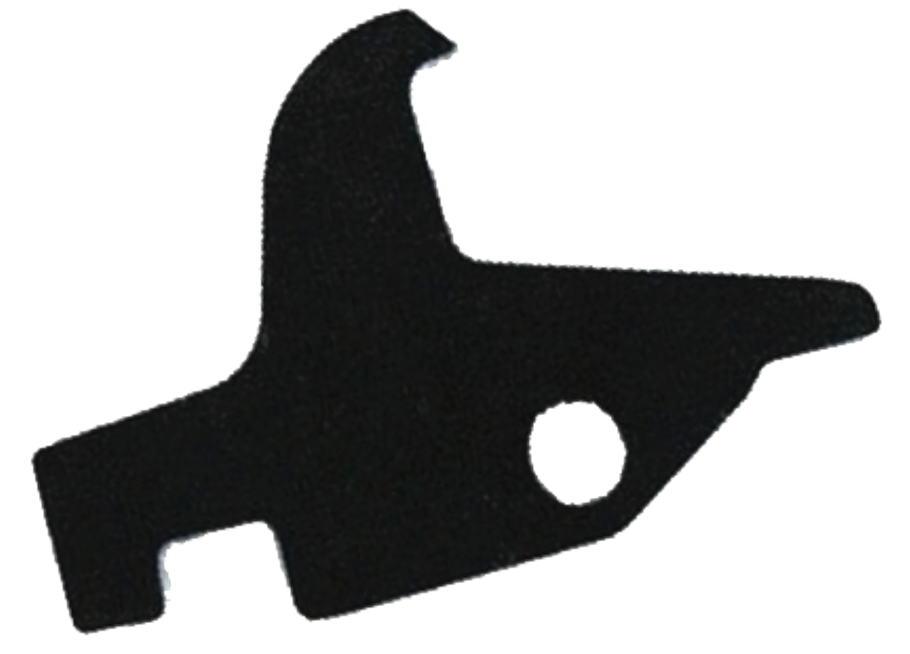

In the intricate mechanics of firearms, bolt stops play a pivotal role in controlling the cycling of the weapon. Dayton Rogers’ precision metal stamped bolt stops contribute to the seamless operation of firearms, enhancing both performance and user experience.

Reliable ignition is fundamental to firearm performance. Dayton Rogers’ precision metal stamped firing pins ensure consistent and dependable ignition, contributing to the overall reliability of firearms.

Ensuring user awareness of the firearm’s status is paramount for firearm safety. Dayton Rogers’ metal stamped loaded chamber indicators provide a reliable visual cue, offering users a quick and clear indication of the firearm’s readiness.

Magazines are integral to the functionality of firearms, and Dayton Rogers delivers excellence in the form of metal stamped magazine bodies. These components are designed and manufactured to withstand the rigors of regular use while ensuring smooth ammunition feeding.

The core structure of any firearm, receivers demand precision engineering. Dayton Rogers’ metal stamped receiver components are crafted with meticulous attention to detail, meeting the highest standards of durability and functionality.

Firearm safety is non-negotiable, and Dayton Rogers takes this responsibility seriously. Their metal stamped safety mechanisms set the industry standard for reliability, providing users with the confidence that their firearms are equipped with top-tier safety features

Efficient shell ejection is critical for the seamless operation of firearms. The precision-engineered shell latches produced by Dayton Rogers guarantee smooth and consistent ejection, even in the most demanding conditions.

The trigger is the heart of any firearm, and Dayton Rogers ensures its reliability through precision-crafted trigger bars. These components undergo rigorous manufacturing processes, resulting in consistent performance and user safety.

Dayton Rogers’ commitment to excellence extends across the entire lifecycle of firearm component production. From the initial design phase to prototyping and finally to full-scale production, the company’s dedicated teams collaborate with clients to engineer the quality components that firearms demand.

The process begins with a deep understanding of client requirements and industry standards. Dayton Rogers leverages state-of-the-art technology and decades of expertise in metal stamping to bring these designs to life. Prototyping ensures that the components meet the exact specifications and functionality demanded by the firearms industry.

Once the prototypes are validated, Dayton Rogers scales up production, utilizing highly efficient metal stamping presses and rigorous quality control measures. The result is a consistent supply of precision metal stamped components that exceed the stringent standards of the firearms industry.

From design assistance to final kitting, Dayton Rogers has you covered!

Contact us today to learn more about the benefits our metal stamping partnerships.

In the competitive firearms industry, cost-effectiveness is as crucial as quality. Dayton Rogers prides itself on delivering high-quality metal stamped components for firearms at a competitive cost. Through efficient manufacturing processes and economies of scale, the company ensures that clients receive top-tier components without compromising their budgetary constraints.

Metal stamping plays a vital role in the firearms industry, providing manufacturers with a cost-effective, precise, and versatile method of producing components. At Dayton Rogers our use of specialized machinery and tools allows for faster production times and consistent results, making it an essential process in the production of firearms. As technology continues to advance, we can expect to see even more advancements in metal stamping, further improving the production capabilities of the firearms industry.

Dayton Rogers stands as a beacon of excellence, consistently delivering precision-crafted components that elevate the performance and safety standards of firearms. From bipods to firing pins, each metal stamped part reflects a commitment to innovation, engineering, and the pursuit of perfection in the ever-evolving world of weaponry.

For those seeking a reliable partner in metal stamping for the firearms industry, Dayton Rogers is just a call away.

Dayton Rogers has led the metalforming industry for more than 90 years, using metal stamping, welding, and fabrication expertise to create a wide array of parts for multiple applications. Our metal stamping and automotive fabrication services create unique solutions that are integral to your firearms project’s success. If you’re ready to discuss our available metalforming methods in a consultation at no cost to you, don’t wait. Call today to speak to one of our metalforming experts about your next automotive project or schedule an in-person meeting.

Want to learn more about metal stamping and fabrication? Get your FREE copy of the Design Principles Red Book. This Design Principles booklet describes the various common conditions that occur in the fabrication of parts.

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved