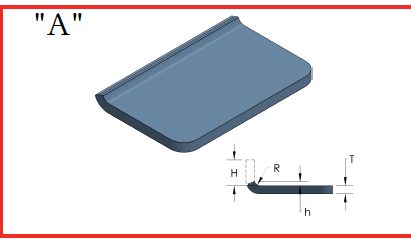

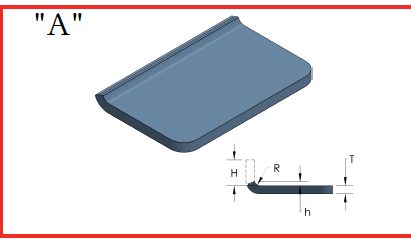

When metalforming, the height of the form is critical. If it’s not correct the first time, it can be a costly mistake to fix. Below you’ll find a quick-reference guide on how to achieve the proper height. Diagram “A” illustrates a 90 degree bend with insufficient height (H) to form properly. Consequently, stock must be … What’s the Right Height for Your Metalforming Part? [FREE CHART]

Now more than ever, medical products are in high demand. When designing metal stamping parts for medical applications, there are a few key considerations that are unique to medical applications. Keep these considerations in mind when designing and choosing metal stamping for the best product. CONSIDERATIONS FOR MEDICAL APPLICATIONS MATERIALS & COATING The right materials … CONSIDERATIONS WHEN METAL STAMPING FOR MEDICAL APPLICATIONS

Dayton Rogers views its business as a problem solving service, in which metal stampings and fabrications are components or end products that fulfill specific requirements. Our professional staff help design and manufacture quality parts that will give you a competitive edge. PROBLEM SOLVING IS THE FIRST STEP TOWARD BETTER METAL STAMPINGS & FABRICATIONS Our approach … Why You Should Choose Dayton Rogers for Metal Stampings and Fabrications

We’ve all seen the rise of electric and autonomous vehicles out on the road. As EV and AV technologies continue to advance, the cars on the roads are following suit. What exactly does this rise in EVs mean for metal stampers? The ever-growing prominence of electric and autonomous vehicles presents new, unique opportunities and challenges … How Metal Stampers are Preparing for the Electric Vehicle Revolution

It’s hard to believe that we’re now living in 2020. We may not have flying cars or robot servants, but many technologies predicted in sci-fi books, movies and TV shows are now a reality. Here’s a look at some current manufacturing technologies that were inspired by science fiction stories. EXOSKELETONS In Aliens, Ripley dons a now-iconic … 5 Manufacturing Technologies Inspired by Science Fiction

Are you considering a project, but are unsure if you should choose metal stamping or fabrication? This handy reference guide will break down the difference between these two methods and which you should choose for your project. WHAT IS METAL STAMPING? Metal stamping is the process of converting flat metal sheets into specific shapes. It encompasses … How to choose Between Metal Stamping and Metal Fabrication

Dayton Rogers is proud to announce that Shalene Singh has been named a 2019 Woman of Excellence in Metal Forming & Fabrication by MetalForming magazine and Women in Manufacturing (WiM). ABOUT SHALENE SINGH Human Resources Manager, Dayton Rogers of Texas, Arlington, TX Shalene has dedicated 15 of her 22 years of industry service to Dayton Rogers. As human resources … Shalene Singh Wins 2019 Women of Excellence in Metal Forming & Fabrication Award

When flattening for your metal stamping project, first need perfect flatness – that condition which exists when all points on a surface lie in the same plane. In order to achieve perfect flatness, you first need to know the flatness tolerance for the surface you’re working with. WHAT IS FLATNESS TOLERANCE? Flatness tolerance is the … Flatness Tolerances for Metal Stamping [FREE CHART]

Carbon steel is a popular choice for metal forming and metal stamping products for the wide variety of finishes and rigidity. When choosing a cold rolled carbon steel strip, it’s important to know what softness is best for your project. Below are the varieties of carbon steel strip you can choose for your project, and for which … How to Choose the Right Carbon Steel Strip for Metal Forming