Automotive Fabrication for Motorsports at Dayton Rogers The fast-paced world of motorsports elicits unparalleled levels of excitement from fans, participants, and engineers alike. There is truly no other venture pursued by manufacturers and fabricators the world over that gets people’s hearts racing the same way that racing itself does. Performance vehicle builds are some of … Automotive Fabrication for Motorsports at Dayton Rogers

How Welding Fabrication Complements Metal Stamping Welding fabrication and metal stamping are two essential processes in the manufacturing industry. While metal stamping involves shaping and cutting metal sheets, welding fabrication involves joining metal pieces together. These two processes often go hand in hand, with welding fabrication complementing metal stamping in many ways. In this article, … How Welding Fabrication Complements Metal Stamping

Can You Really Save Costs with a Custom Metal Stamping? When it comes to metal manufacturing, there are a variety of methods to choose from. Custom metal stamping is one such method, often selected for its ease of setup and quick turnaround time. While standard metal stamping tooling can be effective, there are some cases … Can You Really Save Costs with a Custom Metal Stamping?

Principles of Design for Metal Stamping Metal Stamping Manufacturing Explained If you’re not yet familiar with the manufacturing method known as metal stamping, you’ve come to the right place to learn! Dayton Rogers pioneered the practice of short run metal stampings back in 1929, and we have now been in the metal stamping industry for … Principles of Design for Metal Stamping

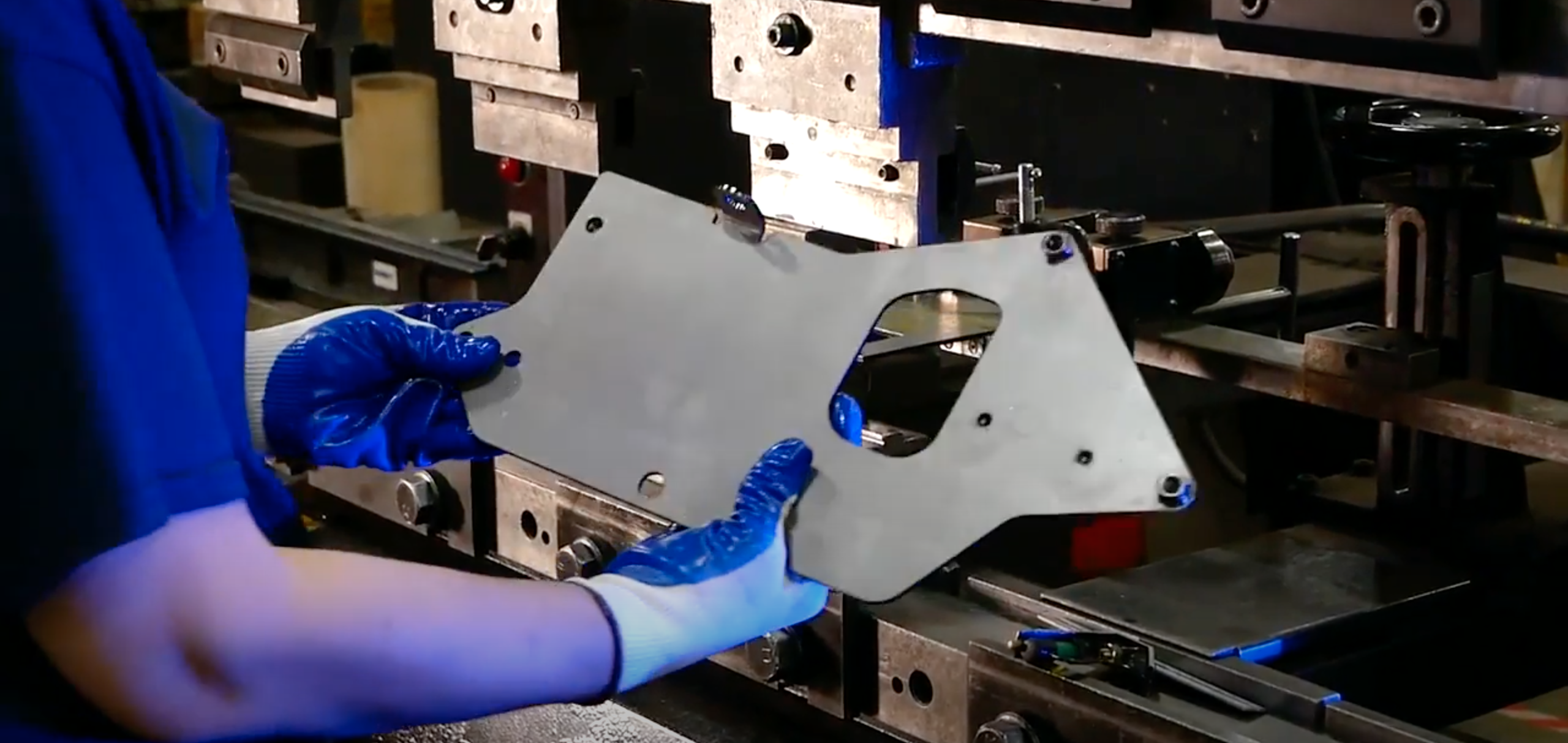

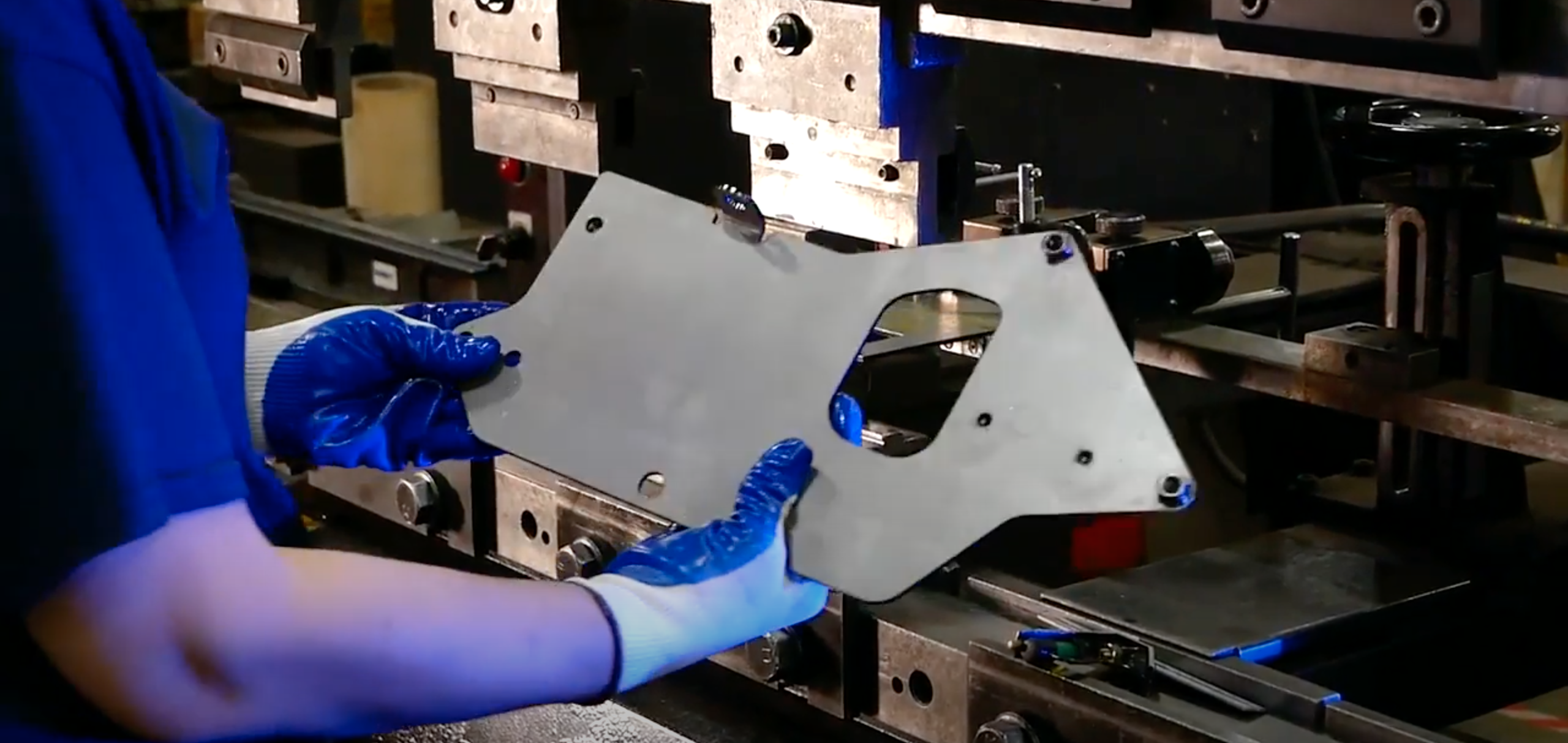

Why Choose Custom Metal Fabrication? It’s no secret that Dayton Rogers is the grandfather of metal stamping. Although metal stamping is our process of choice as it is an incredibly versatile metal forming method, there is no one single process that can truly do it all. Dayton Rogers is dedicated to serving as your one … Add Value and Save Costs with Dayton Rogers’ Custom Metal Fabrication

Challenges of Precision Sheet Metal Fabrication In industries like aerospace, automotive, and electrical, it is imperative for components to be produced to spec. Even in cases where tolerances are extremely tight, any slight deviation from the outlined parameters can be detrimental to the function of the overall completed product. While it’s easy to understand why … High Precision Made Simple with Modular Stamping

At Dayton Rogers, short run metal stampings are one of our key offerings. Short run metal stampings are just what they sound like: they are metal stamping projects with a low finished part volume. What quantity exactly qualifies as ‘short run’ depends on the metal stamper that you ask, but generally any order less than … 3 Types of Short Run Metal Stampings

You may be surprised to learn that we go beyond just metal stamping to serve as a one-stop shop for all of your sheet metal forming needs. Here at Dayton Rogers, we pride ourselves on being able to serve our customers with a wide range of custom metal manufacturing solutions including laser cutting and welding. … Custom Metal Manufacturing at Dayton Rogers

Metal stamping and fabrication are two distinct metalforming techniques used to create all kinds of products imaginable. From commonly used items like washers to high precision aerospace and medical parts, metal stamping and fabrication provide the range to do it all. Depending on your particular project requirements, one metal manufacturing method may be better than … What are Metal Stamping and Fabrication