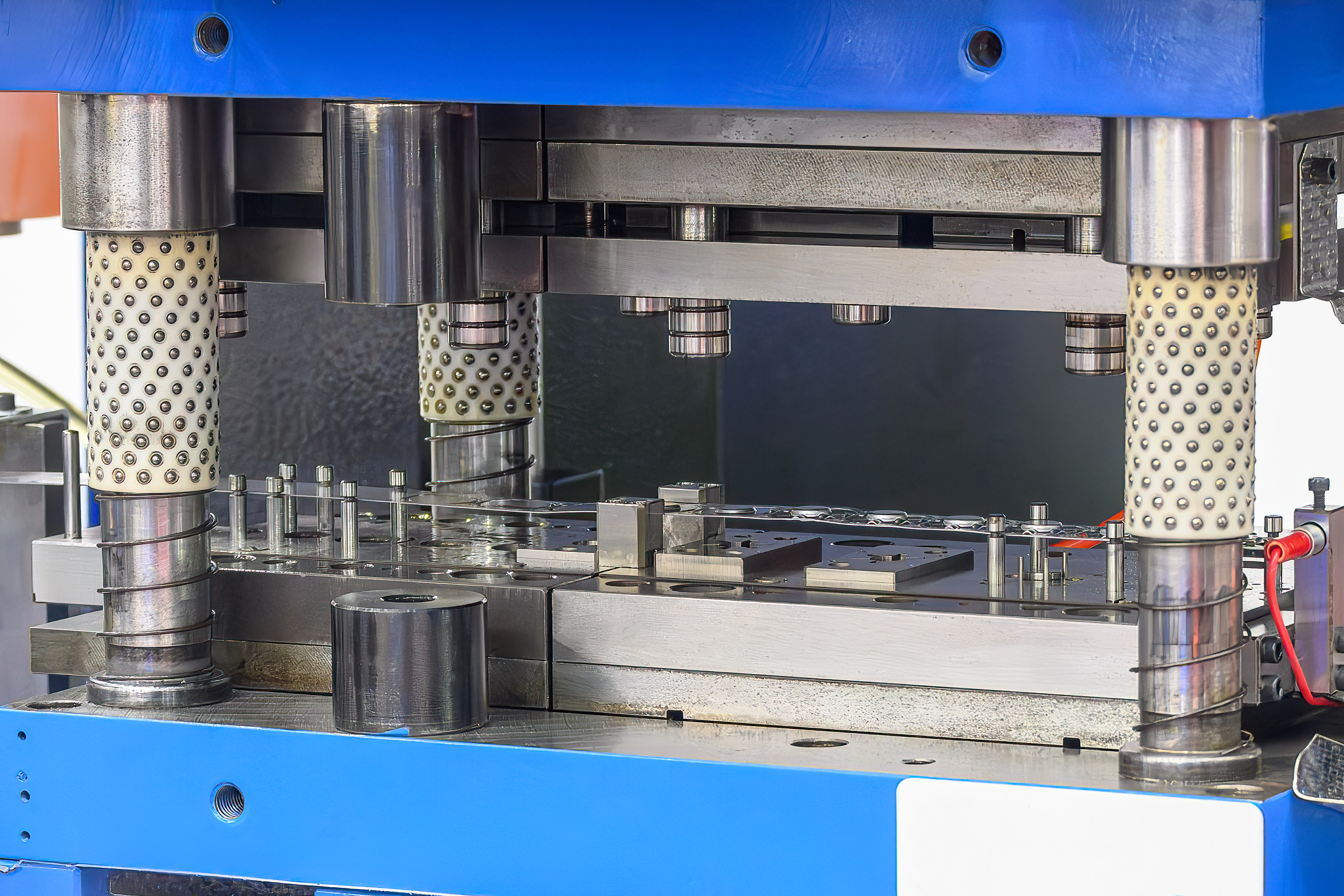

Types of Tooling for Short-Run Metal Stamping Explained Tool and die-making is an intense process that plays a key role in creating countless parts that are part of our everyday lives. Beyond that, it is also an intricate skill that requires years of training to enter, and decades of experience to master. In today’s article, … Types of Tooling for Short Run Metal Stamping Explained

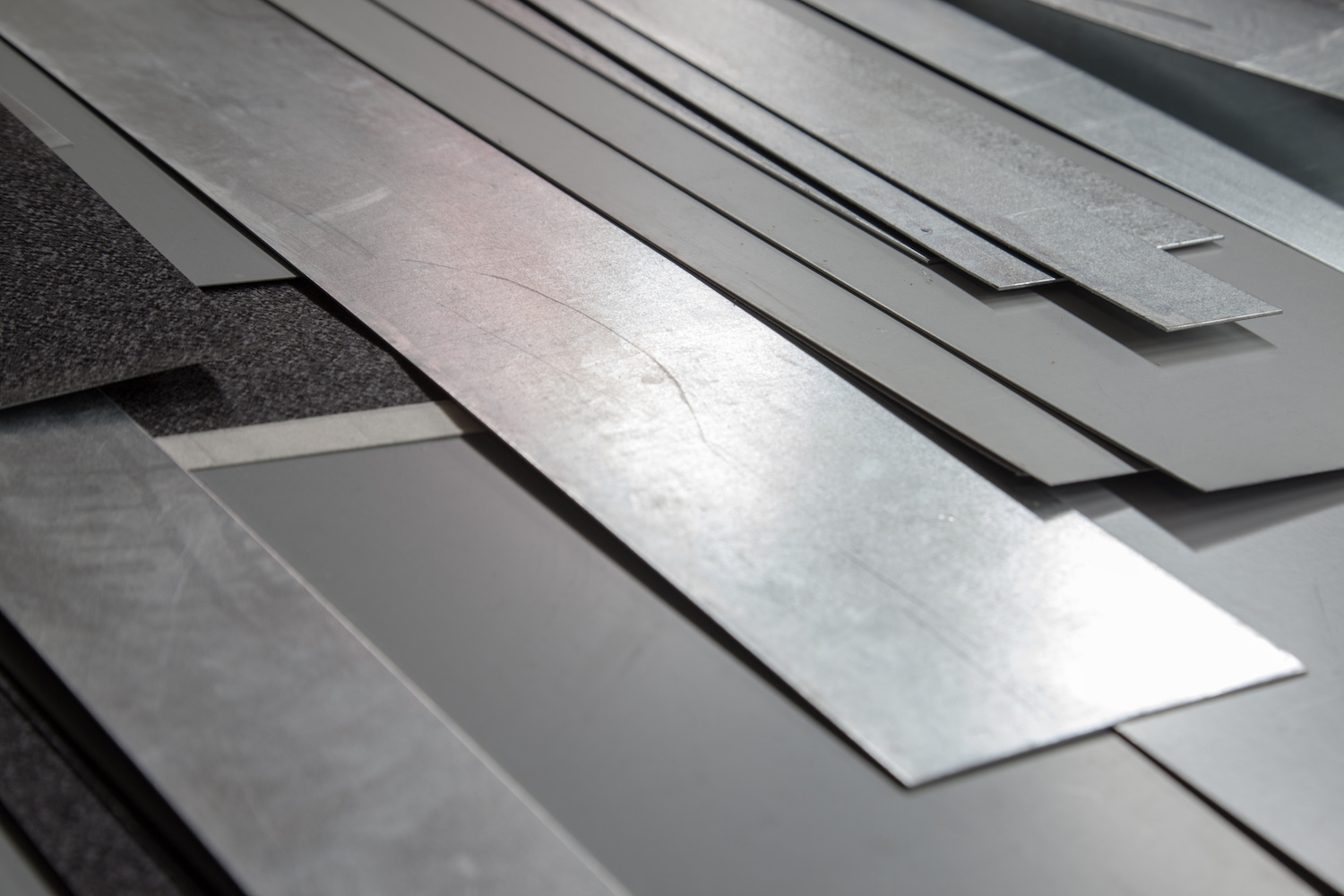

When flattening for your metal stamping project, first need perfect flatness – that condition which exists when all points on a surface lie in the same plane. In order to achieve perfect flatness, you first need to know the flatness tolerance for the surface you’re working with. WHAT IS FLATNESS TOLERANCE? Flatness tolerance is the … Flatness Tolerances for Metal Stamping [FREE CHART]

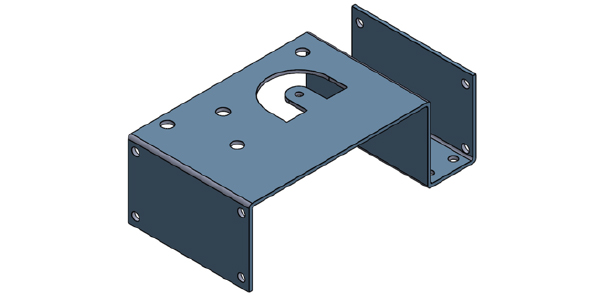

Comparing cost impact of the several variables is difficult. To help explain the impact, we have selected a sample part and shown the price range that you could reach depending on how you control your design. Low Cost Design Tolerance: + .010 on centers — + .005 on hole diametersMaterial: 16. ga. 1010 sheet — … Typical Parts Price Comparison of Variations in Materials and Design/CAD

Here at Dayton Rogers, we live and breathe metal stampings. As an authority on the subject and stamping fanatics, we often forget that not everyone is familiar with how different types of stampings work. You may have heard the terms “short run stamping” and “progressive stamping” before. What exactly is the difference between the two? … Short Run Stamping vs. Progressive Stamping: Which is Right for Your Project?

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved