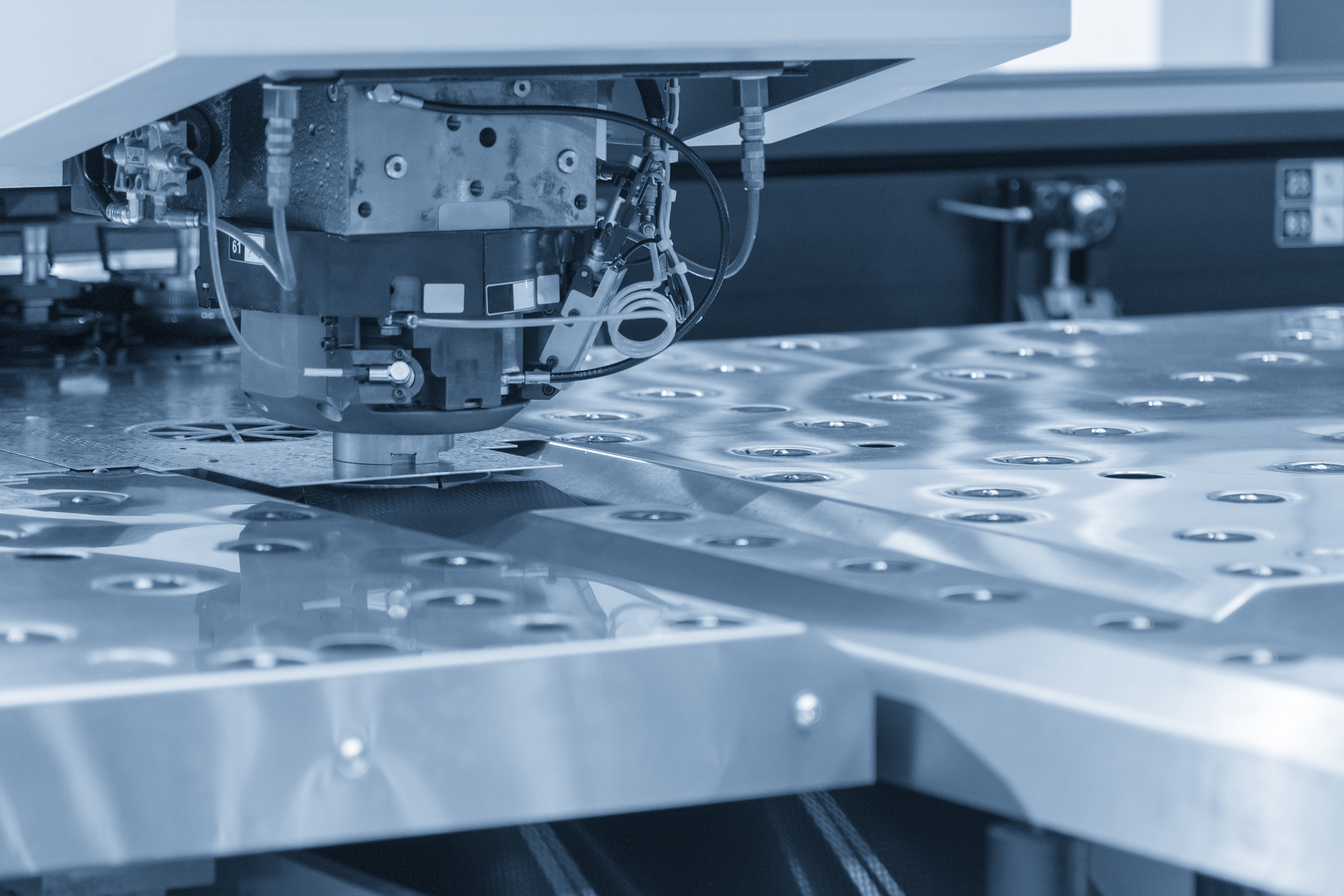

Benefits of a Manufacturer with a Broad Service Offering

When it comes to metal manufacturing services, a single line of purchasing for fabrication needs is ideal for a variety of reasons. Instead of having to go to multiple businesses, you can just go to one location for all your needs. Deciding to outsource multiple manufacturing services from a single shop is much like shopping … Benefits of a Manufacturer with a Broad Service Offering