Posted: Aug 18, 2023

You may be surprised to learn that we go beyond just metal stamping to serve as a one-stop shop for all of your sheet metal forming needs. Here at Dayton Rogers, we pride ourselves on being able to serve our customers with a wide range of custom metal manufacturing solutions including laser cutting and welding. Best of all, our custom metal manufacturing services are available with little to no additional tooling costs to you! Let’s explore some of the additional fabrication services that we offer and how they tie in with our metal stamping processes.

Laser cutting is a manufacturing method which uses a focused beam of light to cut through metal sheets. This laser is programmed to follow a set cutting path with the use of a computer, so cuts can be repeated multiple times with minimal variation.

This method has a few common applications. One of these is cutting precision blanks out of sheet metal for parts with a tight tolerance. These precision blanks can then be used for metal stamping. Another use for lasers is to cut tight-tolerance features into a blank. Some of the most common features created with laser cutting are thin slits and holes for ventilation.

Thanks to the focus of the beam, laser cutting offers an incredibly precise edge finish. Our machines are capable of wattage anywhere from 2,000 to 4,000 watts of power to tackle any laser cutting project with ease.

One of the greatest benefits of laser cutting comes from the ability to automate the process. Here at Dayton Rogers, we engage in a practice called lights-out manufacturing. Simply put, this means that our laser cutter can keep doing its job without the need to be monitored by any personnel. This machine works nonstop, which results in great cost savings for your order!

Our most versatile offering beyond metal stamping is our welding fabrication. We offer four types of welding: spot welding, arc welding, MIG/TIG welding, and robotic welding.

Spot welding is the simplest of all the welding processes, which by extension also makes it the quickest and most cost-effective method that we offer. This type of welding is commonly used to weld metal sheets together, creating a permanent bond between the two.

For a more substantial joint between components, we also offer arc welding. Like spot welding, this process is relatively simple and quick to perform. The main difference is that arc welding allows us to produce a continuous weld rather than just one spot at a time. This method is substantially more versatile when compared to the other welding options we offer. Our skilled technicians expertly apply a professional grade weld to ensure a strong bond on your final piece.

MIG and TIG are used for welds where high strength is critical. They both employ very high heat and slow cooling times to make an incredibly durable joint between parts. These methods also allow us to weld different metals and alloys to each other, so working with mixed materials is not a problem. Each method calls for the use of a filler material to bond the two metal pieces together, which is selected based on the materials to be joined. The welds produced by MIG and TIG are shielded by an inert gas, which makes them visually more appealing than flux-shielded arc welds.

Our robotic welding equipment is the most advanced of our current weldment offerings. This method is best suited for high production, high precision applications where repeatability is made easy thanks to the use of a programmed weld path. We recommend this type of weld for high-precision applications.

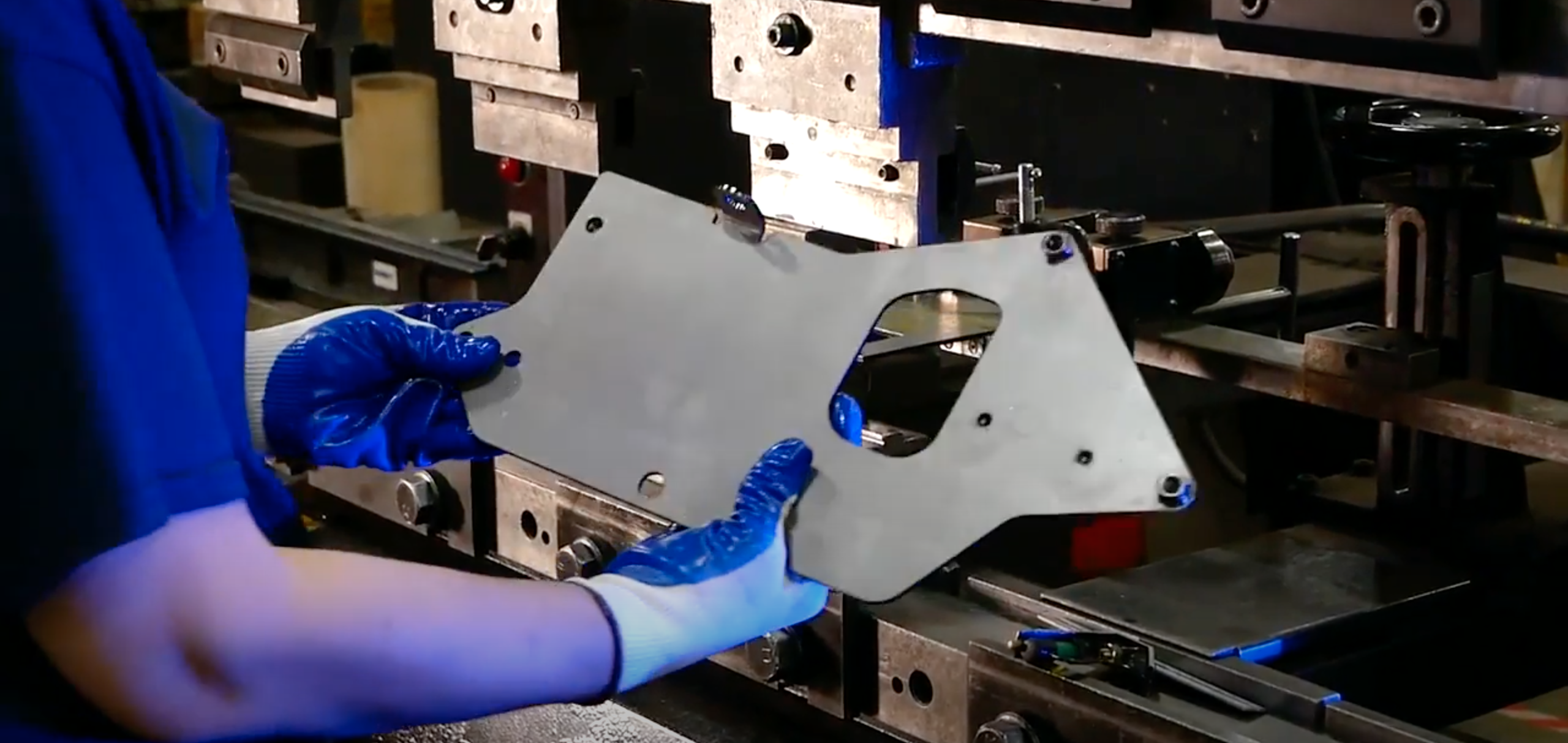

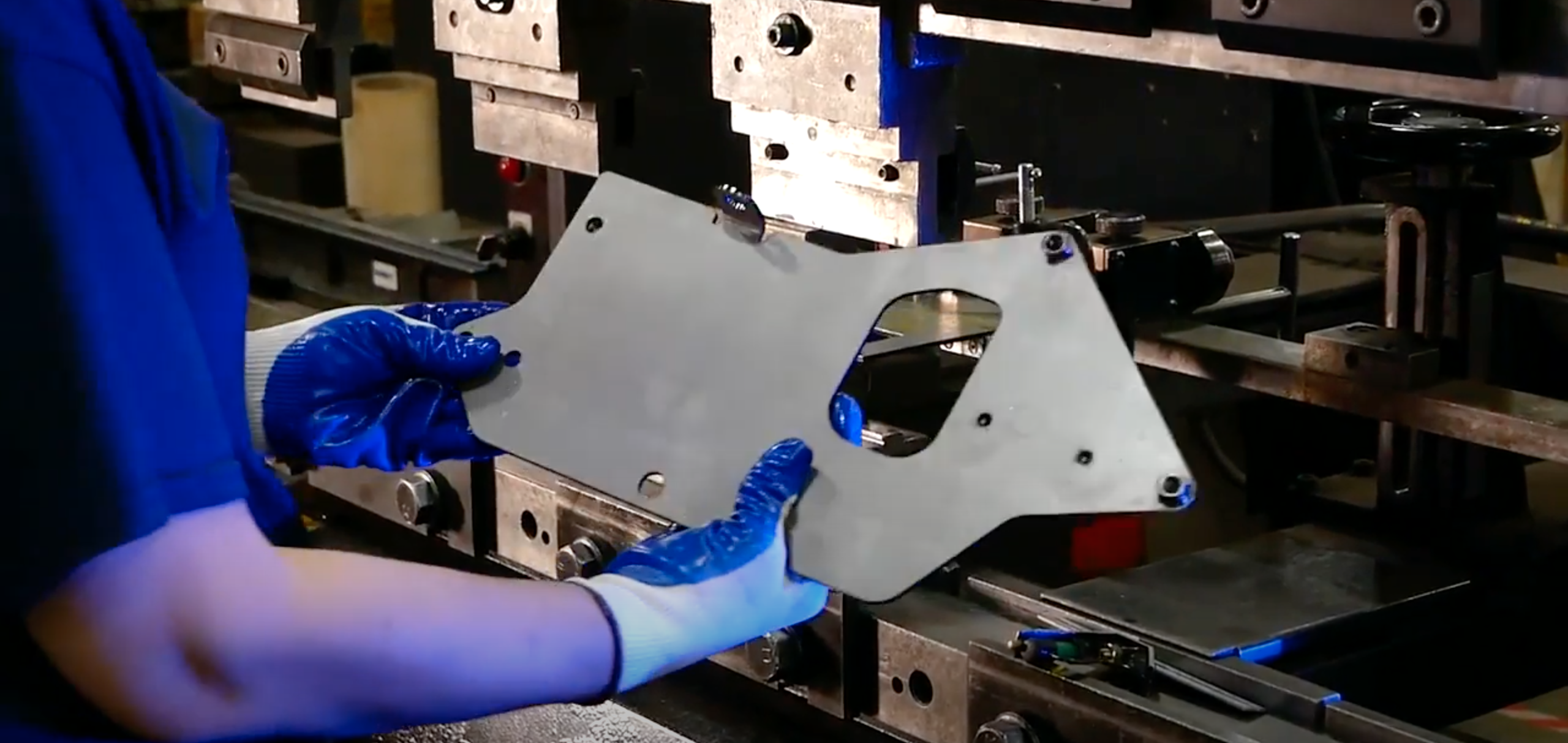

This wouldn’t be a comprehensive list of Dayton Rogers’ custom metal manufacturing services if we didn’t discuss our key offering: metal stampings.

We specialize in short run metal stampings to produce complex parts at a fraction of the cost compared to other metal manufacturing processes. Each run can produce a small quantity of parts for prototyping purposes, or up to hundreds of thousands of parts for a full-fledged production run.

Metal stampings offer superior quality control to other manufacturing methods and can replace even complex casting and machining processes to deliver the part that you need. Our engineering team is highly experienced in optimizing customer projects to make the switch from more complex fabrication methods to metal stamping, saving both time and manufacturing costs.

Dayton Rogers is a trusted authority in all things metalforming. With our decades of experience in the industry and fully equipped shop space, we guarantee that we can bring your next custom project to life better, faster, and cheaper than the rest. That’s the Dayton Rogers difference.

Dayton Rogers has led the metalforming industry for more than 90 years, using stamping and fabrication expertise to create a wide array of parts for multiple applications. Our metal stamping and metal fabrication services create unique solutions that are integral to your project’s success. If you’re ready to discuss our available metalforming methods in a free consultation, don’t wait. Call today to speak to one of our metalforming experts about your project or schedule an in-person meeting.

Our four locations dispersed across the United States position us as a nationwide authority on all things metal stamping. We have locations in the busiest manufacturing hubs in the country, including:

Dayton Rogers holds PMA membership in the Southeast district, Twin Cities district, and the Lone Star district along with a general membership. At all of our locations, we remain dedicated to repeatable precision manufacturing.

Want to learn more about metal stamping and fabrication? Get your FREE copy of the Design Principles Black Book. This Design Principles booklet describes the various common conditions that occur in the fabrication of parts.

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved