Posted: Jun 22, 2021

Metal stamping has been a critical component of the manufacturing industry since the industrial revolution. In fact, one of its earliest use cases was in Germany to produce frames and handlebars for bicycles. Since then, it has evolved into an essential part of the production of parts and components for a wide variety of industries including automotive, aerospace, medical, and others.

How It Works

As you may know, metal stamping is a cold-forming process that uses dies and stamping presses to transform sheet metal into different shapes. Essentially, metal stamping converts flat sheets of metal into specific shapes. And, as global markets evolve, there is an escalated need for timely production of large quantities of complex parts. Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need.

Because metal stamping started over 100 years ago, many updates have been made since then. Many of these improvements are thanks to the advancements in technology over the years including the introduction of computer numerical control (CNC) where designs are created and tested on a computer and then fed into a CNC metal stamping machine. Before the materials can be formed, however, their tooling must be designed using CAD/CAM technology, another tool that has taken metal stamping to new heights.

Once the designs are approved and as precise as possible, the metal stamping process can move forward. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Deep Draw Stampings

Even the most complicated metal stamping projects, simplified by the experts at Dayton Rogers, and manufactured to your exacting specifications.

Equipment & Capabilities

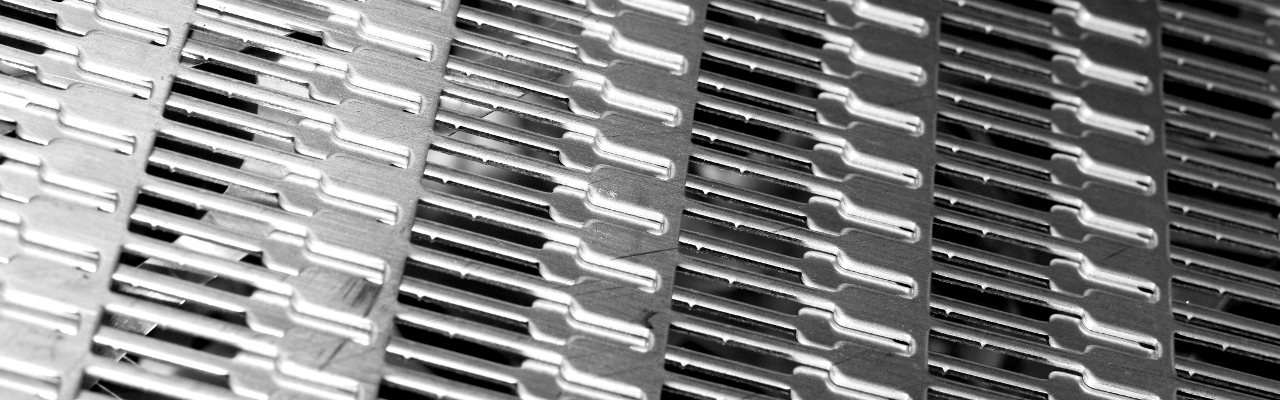

Progressive Stampings

For quantities exceeding modular or laser production, progressive tooling provides quality stamped components at the best price. Coil-fed progressive dies produce a finished part with every stroke of the press.

Equipment & Capabilities

Modular Stampings

Modular tooling for metal stamping offers amazing precision and required repeatability. We are diligent about maintaining optimum equipment standards and functionality, keeping your lead-time minimal. This is a cost-effective option between progressive and laser.

Equipment & Capabilities

Prototyping to Production

If your organization is interested in saving time and money, reducing stress, increasing efficiency, and staying ahead of the competition, Dayton Rogers can help. We offer a variety of in-house capabilities including metal stamping, fabrication, welding, machining, and complete assemblies. We are proof of why working with one supplier for multiple services can take your organization to the next level.

As you can see, metal stamping is a major part of the manufacturing industry and it will continue to play an important role in the production of future parts for a wide range of industries. For more information on Dayton Rogers’ metal stamping capabilities, please contact our team or visit our website here.

About Dayton Rogers

For nearly a century, Dayton Rogers has defined engineering and manufacturing in the metal-forming industry. We not only raised the bar, we created it. At Dayton Rogers, no project is too complex. In fact, we do 3D prototyping to production.

As pioneers in precision metal forming, Dayton Rogers introduced its vision of excellence in 1929 with a simple commitment – to create solutions that are integral to your success. From metal stamping to welding and sheet metal fabrication, our brilliantly engineered solutions are innovative and reliable.