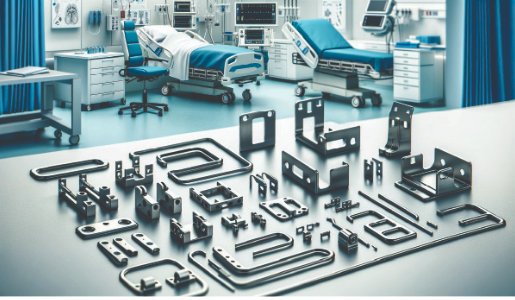

The medical industry is one of the most demanding, requiring small metal parts with intricate geometries fashioned from some of the most difficult to form materials. With the added requirements of cleanliness and advanced precision, the ability to design for medical metal fabrication and manufacture to spec is no small feat. At Dayton Rogers, we draw from 95 years of experience in high quality precision stamping and sheet metal fabrication to exceed the expectations of the medical industry. We have a proven history of forming metal parts for use across the medical sector including:

Beyond product design, precision manufacturing is critical to the success of metal parts used in medical equipment. We employ the following methods of metal stamping for the medical industry to ensure that your project’s needs are met with precision:

Progressive stamping allows us to create high quality metal components with guaranteed repeatability between cycles. Progressive tooling ensures the highest degree of accuracy for both short run metal stamping projects and long run metal stamping partnerships.

Modular stamping keeps tooling costs low and production quality high. Our wide library of modular tooling allows us to craft simple and complex metal components to meet your specifications in a timely manner.

Deep draw metal stamping is particularly well-suited for producing complex, three-dimensional shapes with deep recesses and intricate features. Metal components that require such characteristics, like housings and casings, often benefit from the advantages of deep draw metal stamping.

For larger components, we offer a host of metal fabrication methods to complete your project with the precision and speed that you need. Using advanced machinery including laser cutters and robotic welders, our fabrication team can expertly form parts like:

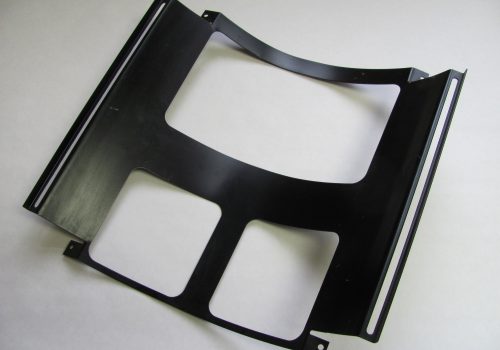

In a medical setting where hygiene is imperative, a nonmetallic layer can act as a barrier to protect the cleanliness of your metal parts against the threat of corrosion. That’s what makes our powder coating service ideal for manufacturers of medical equipment including framework, device enclosures, mounts, and more. Our custom powder coatings are applied by hand for a level of quality control that automation just can’t match. Find out more by contacting Dayton Rogers of TX today.

Powder coating only available at

Dayton Rogers of TX.

There is no room for error in medical component manufacturing, so we take every possible step to facilitate your project’s success. We offer complete turnkey assembly and kitting solutions to ensure efficient and secure distribution of your medical components and piece parts. Whether you need simple labeling and bagging or more complex assembly operations, Dayton Rogers can do it all. .

Dayton Rogers is ISO 9001 certified at all 4 locations, giving you the peace of mind that can only come with choosing a quality contract supplier. Check out our Quality Certifications page for more info, including downloadable copies of our current ISO certifications.

With 4 locations centered around the busiest manufacturing hubs in the U.S., we continue to expand our services while helping you achieve your vision. You can find Dayton Rogers Manufacturing Co. at the forefront of metalforming manufacturing in the 4 following states:

MEDICAL METAL FORMING NEAR MINNEAPOLIS, MN

8401 West 35W Service Drive

Minneapolis, MN 55449

MEDICAL METAL FORMING NEAR COLUMBUS, OH

2309 McGaw Road West

Columbus, OH 43207

MEDICAL METAL FORMING NEAR NEWBERRY, SC

12223 C R Koon Hwy

Newberry, SC 29108

MEDICAL METAL FORMING NEAR ARLINGTON, TEXAS

1107 Commercial Blvd N

Arlington, TX 76001

For low-volume medical equipment like custom cart enclosures or MRI housings, we recommend Sheet Metal Fabrication (Laser/Turret/Brake), as it requires no hard tooling. For high-volume components like hospital bed brackets or monitor mounts, Progressive Die Stamping is the superior choice, offering the lowest piece-part price and strict part-to-part repeatability required for automated assembly lines.

Yes. We specialize in sheet metal fabrication for medical enclosures, including device carts, control consoles, and electronic chassis. Unlike stamping, which is size-constrained, our fabrication department can produce large, complex weldments and assemblies. We can then install smaller stamped internal components (which we also manufacture) to provide a complete, turnkey mechanical solution.

Yes. We support the full medical product lifecycle. We use Laser Cutting and Soft Tooling to produce functional prototypes for clinical trials and validation without the high cost of hard tooling. Once your design is locked, we seamlessly transition to Progressive Die Stamping for scalable, high-volume production.

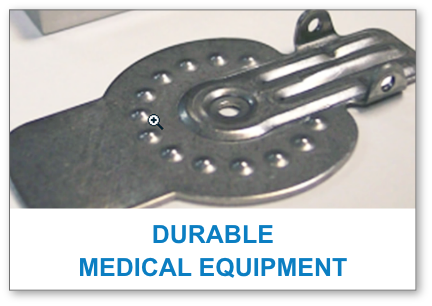

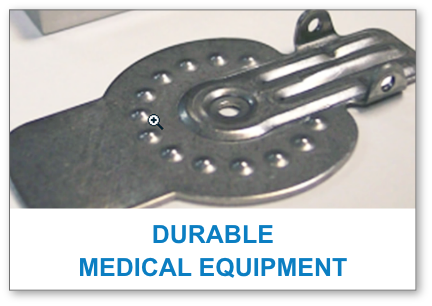

e specialize in components for Durable Medical Equipment (DME) and non-invasive devices. Our portfolio includes hospital bed frames, CT/MRI scanner structural parts, dialysis machine panels, and physical therapy equipment. We focus on structural, enclosure, and mechanism components and do not manufacture implantable medical devices.Accordion Content

We maintain ISO 9001:2015 certification across all four of our US locations. Whether utilizing laser cutting for prototypes or progressive dies for mass production, we employ advanced statistical process control (SPC) and in-die sensing to ensure every part meets the tight tolerances required for medical assembly and patient safety.

8401 West 35W Service Drive, Minneapolis, MN 55449-7260 1-800-677-8881

© 2022 Dayton Rogers. All rights reserved