Posted: Jul 6, 2020

Blanking is a manufacturing process where a flat shape (or blank) is created from a strip of metal through punching. Blanking is a core part of metal forming and stamping. When creating metal blanks, there are a few rules to keep in mind.

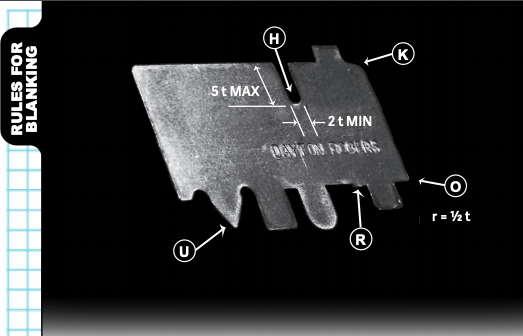

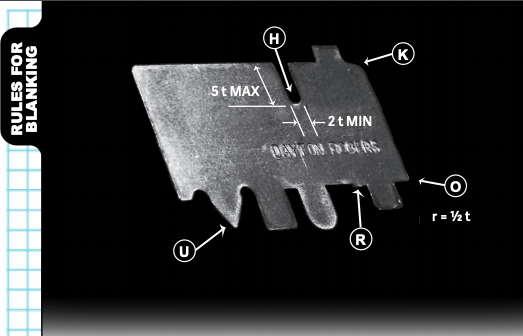

(K) This is a sharp corner as it comes out of the die for this thickness, temper and type of material.

(O) This is a corner with a radius equal to ½ the stock thickness. This radius can be included in the blank at no additional cost for tools or operations.

(R) This is a slight step with a sharp internal and external corner included in the contour of the blank. Pull-down on the die side and breakage on the burr side prevents better definition. Thickness, temper and type of material will vary the results similar to explanation (K) above.

(H) This notch is wide enough relative to its length and material to include in the blanking die. The blanking die cost would be a little higher, but would be cheaper than the possibility of notching tools, plus the extra operation.

(U) The same explanation as (H) above, applies to the two relief notches on either side of this form.

Following these rules will ensure a desired metal blank. Want more metalforming and metal fabrication tips for designers and engineers? Get your FREE copy of the Design Principles Black Book. This Design Principles booklet describes the various common conditions that occur in the fabrication of parts.

Download the Design Principles Black Book

Dayton Rogers is your trusted resource for sheet metal fabrication, metal stamping, metalforming and all your manufacturing company needs. Get a free quote today on your custom metal fabrication project.

LOCATIONS