Posted: Oct 10, 2019

Carbon steel is a popular choice for metal forming and metal stamping products for the wide variety of finishes and rigidity. When choosing a cold rolled carbon steel strip, it’s important to know what softness is best for your project. Below are the varieties of carbon steel strip you can choose for your project, and for which applications each type is best suited.

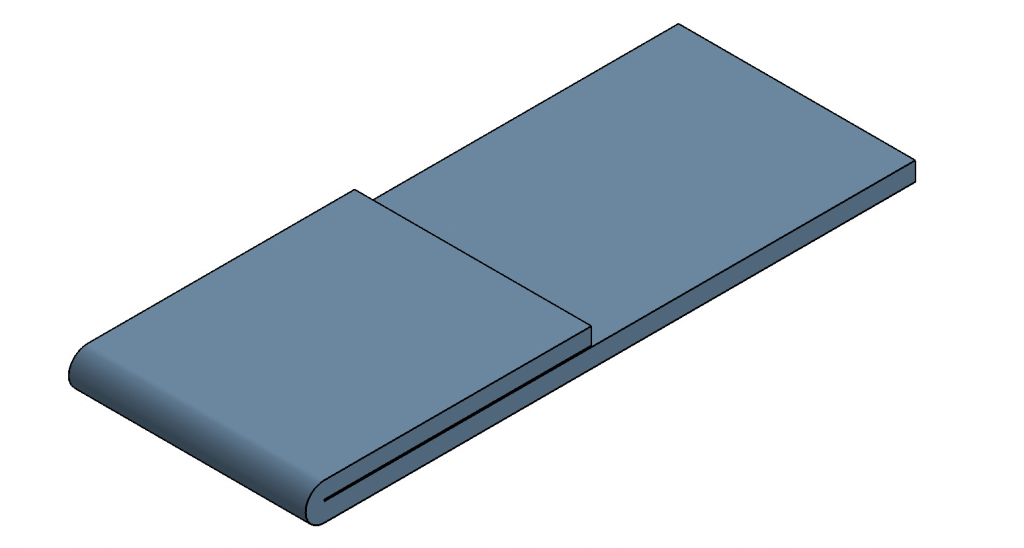

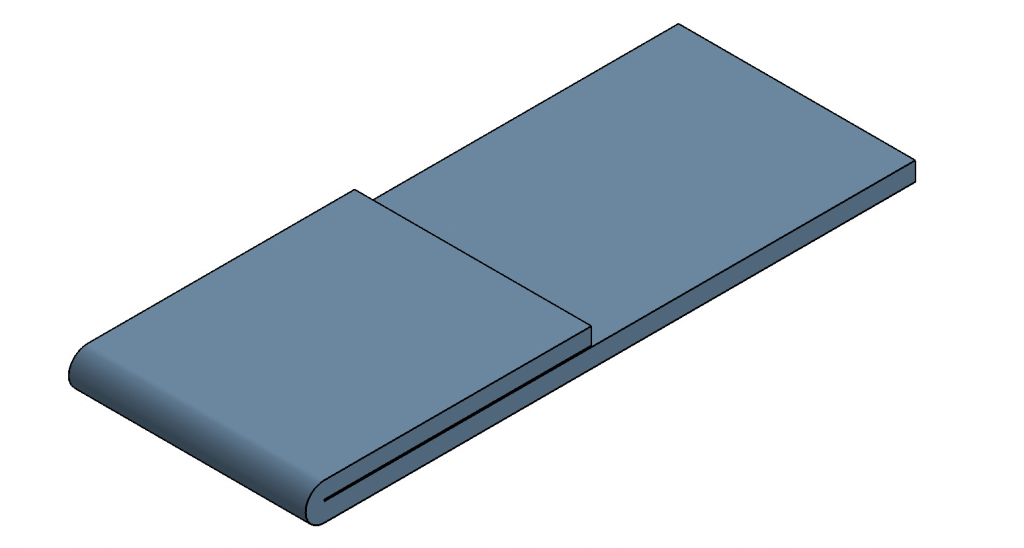

For stamping or punching flat pieces requiring rigidity and strength.

For simple blanking operations. Will bend at sharp right angle across the grain (direction of rolling).

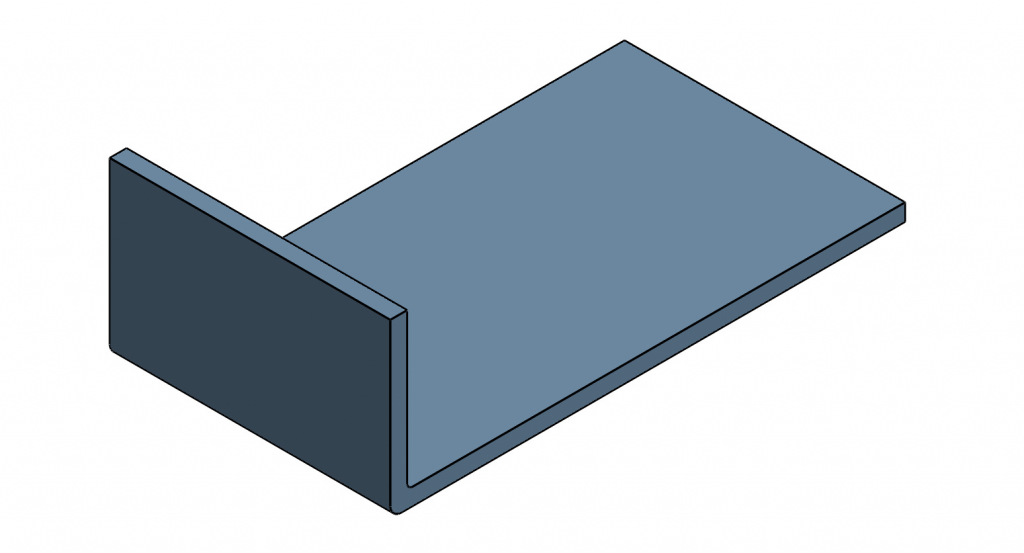

Will bend flat on itself across the grain. Takes some bending with the grain.

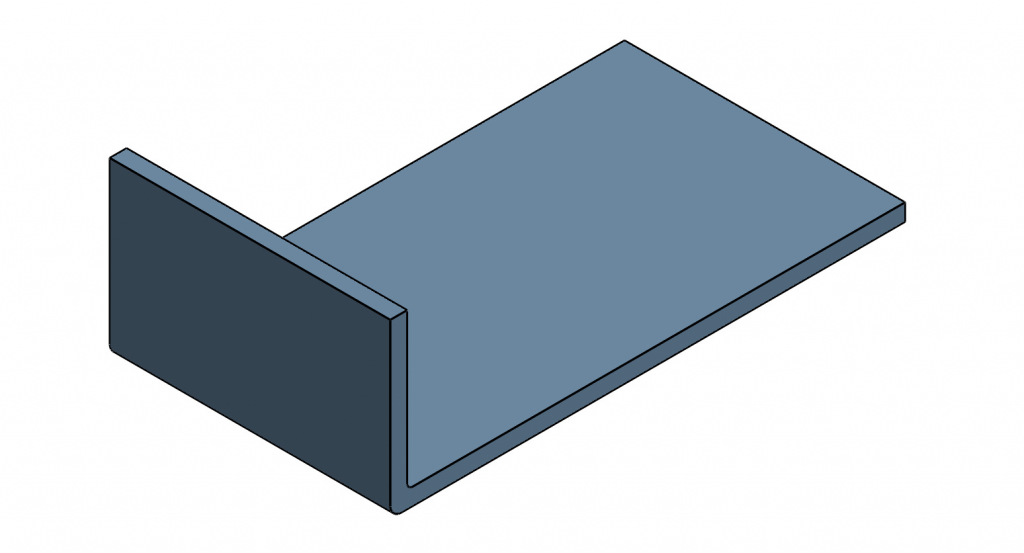

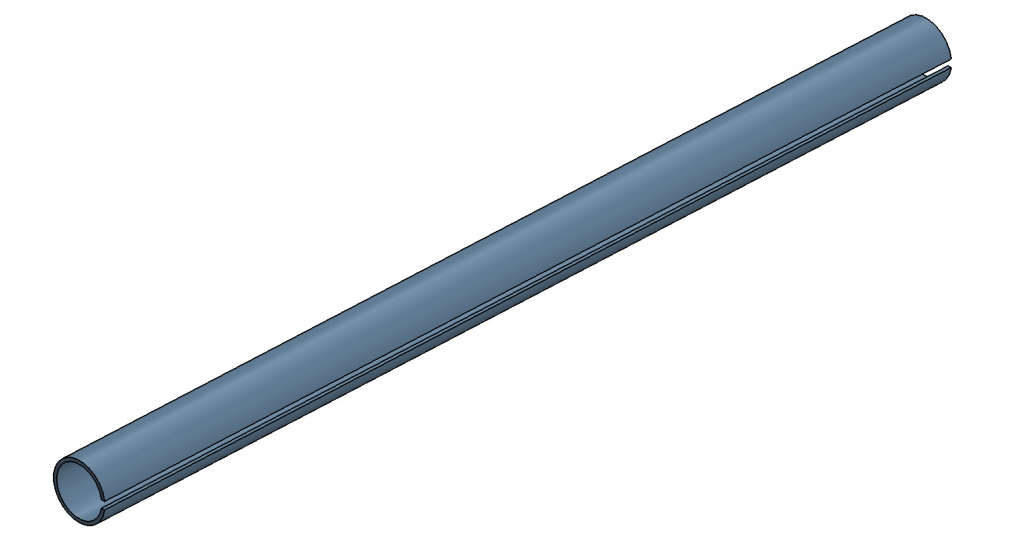

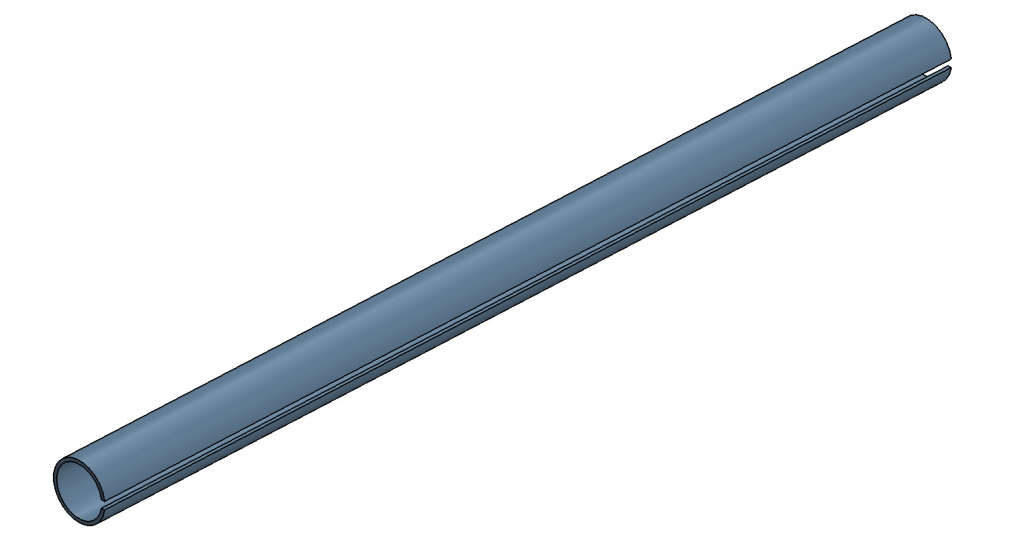

For tubing, moulding, some deep drawing. Will bend both directions of the grain.

For deep drawing and difficult forming. Extremely soft, it will bend flat on itself both directions of the grain.

Unsure which carbon steel strip to choose? Contact us for guidance on your project.

Want more metalforming and metal fabrication tips? Get your FREE copy of the original Dayton Rogers Red Book. This powerful book is your resource for all things metalforming and stamping.

Dayton Rogers is your trusted resource for sheet metal fabrication, metal stamps, metalforming and all your manufacturing company needs. Get a free quote today on your custom metal fabrication project.

LOCATIONS

● MINNEAPOLIS 8401 West 35W Service Drive Minneapolis, MN 55449

● TEXAS 1107 Commercial Blvd N Arlington, TX 76001

● OHIO 2309 McGaw Road West Columbus, OH 43207

● SOUTH CAROLINA 1020 Second Avenue Columbia, SC 29209